Comparison of Rx-7 13B-REW and Supra 2JZ-GTE sequential turbos

#1

Comparison of Rx-7 13B-REW and Supra 2JZ-GTE sequential turbos

Sequential Turbos Demystified

FD Emissions control systems

FD cooling fan control system

Power FC Commander tuning

Electronic Boost Controller Comparison Chart

For a long time I’ve been wondering about the differences between the Rx-7 sequential twins and the Supra sequential twins. Both systems were originally designed for luxury cars (Mazda Cosmo and Toyota Aristo/Lexus GS) and then adapted for sports car use. So are the 2JZ sequential turbos simpler than the 13B/20B sequential turbos? Are they inherently more reliable? Having developed the 2JZ turbo system after Mazda, what did Toyota do differently and did Mazda “miss” something in their system design that Toyota figured out later?

To answer these questions, I searched through Mazda and Toyota technical papers on the respective engines. I searched though technician training/service highlights documents. I looked through workshop manuals and websites. I also physically examined the actual components in-person.

The Short Answer

Both systems have the exact same number of actuators and each actuator has basically the same overall purpose. The 2JZ has fewer solenoids and less plumbing compared to the 20B/13B design, while the actuators themselves are simpler. The 2JZ sequential twins are hardly bulletproof but they do have less failure points. However, the design of the 2JZ sequential turbo system inherently requires more space, and thus its architecture may not have even been possible with the packaging constraints of the Rx-7 and Cosmo.

Overview of how each engine's turbo system works

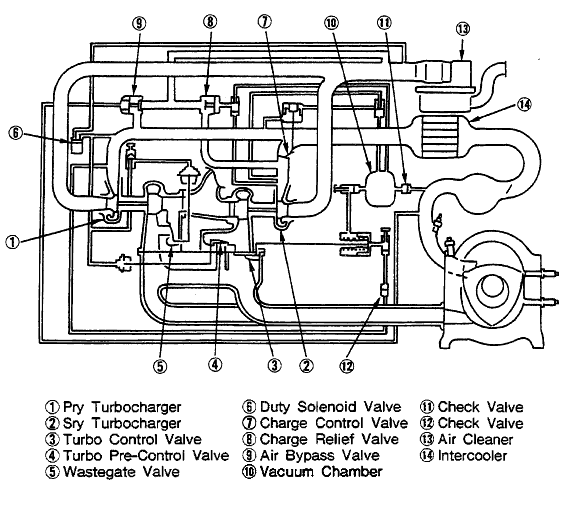

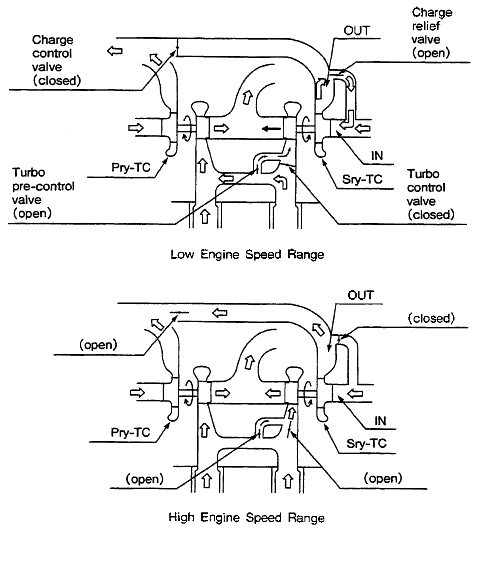

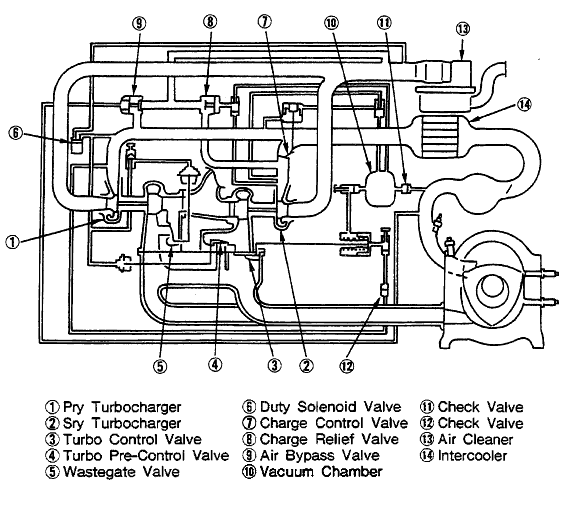

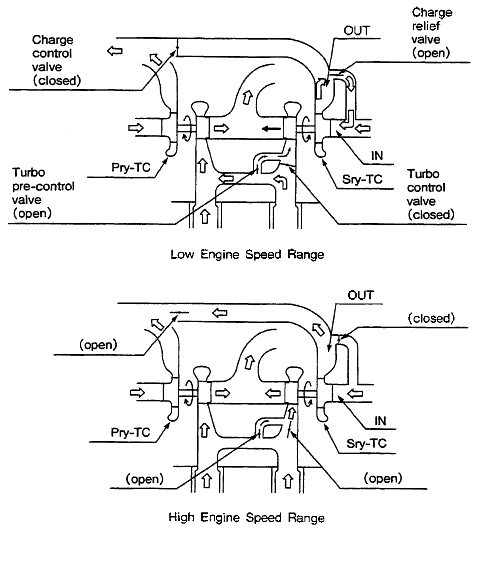

I know this is going to be hard to follow, but here is the basic idea of how the 13B-REW twin turbos work. As the driver starts from low rpm all exhaust gas flows into the primary turbocharger. As rpm increases and boost begins to reach a predetermined level, exhaust is diverted away through a small valve upstream of the secondary turbo. This valve regulates boost while allowing gases from the exhaust manifold to feed the secondary turbo.

As the secondary turbo spins up, on the compressor side a valve prevents its pressurized air from entering the engine. Instead another valve in the Y-pipe diverts that compressed air back to the intake until the secondary turbo is fully ready. When it is time for both turbos to run together, yet another valve opens upstream of the secondary turbo exhaust housing in order to feed it as much exhaust gas as possible. The compressed air from the secondary turbo compressor outlet is then allowed to flow into the engine. Finally a wastegate becomes the sole means of controlling boost by diverting exhaust gas upstream of the primary turbo and out towards the downpipe. The basic operation of the secondary turbo is controlled by two valves upstream of the exhaust side, before the turbine inlet.

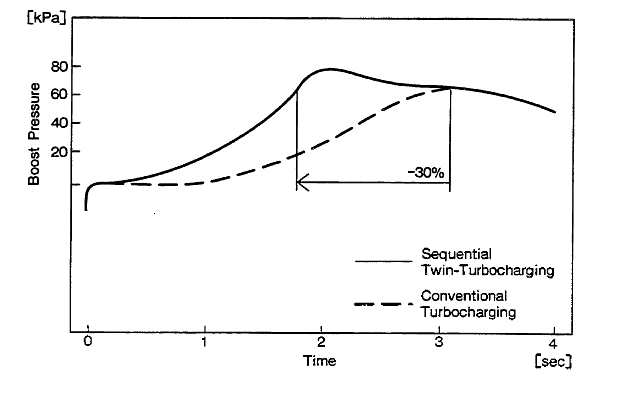

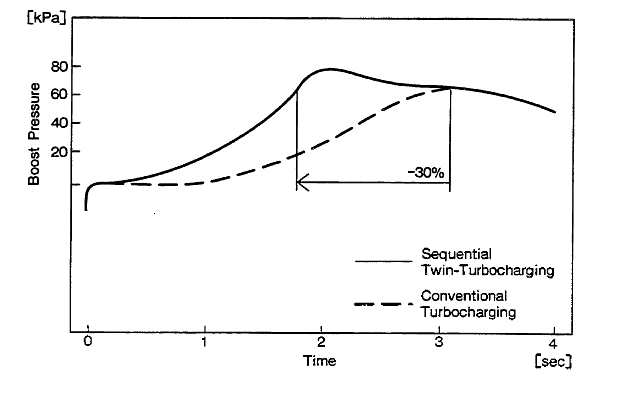

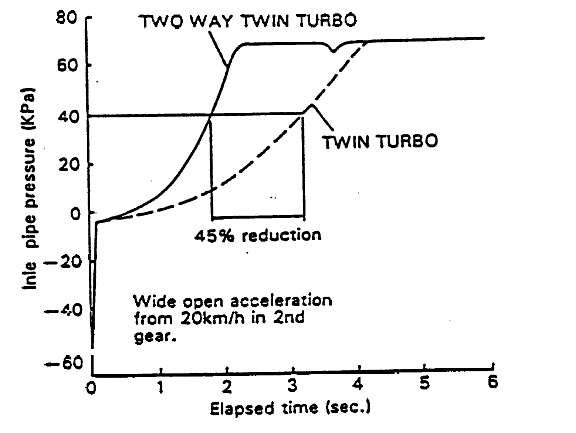

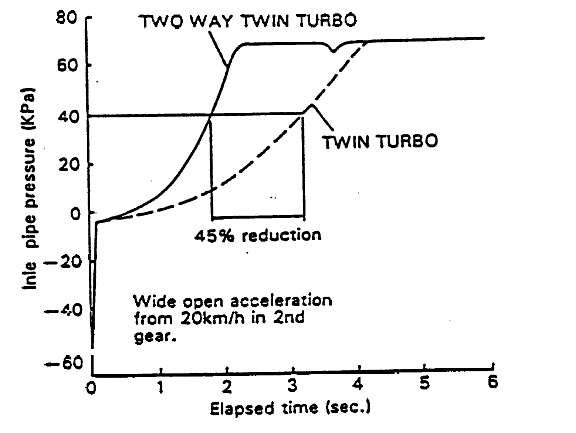

(Sequential Twin Turbo is the production system; conventional turbocharging is a benchmark from a prototype used in development)

FD Emissions control systems

FD cooling fan control system

Power FC Commander tuning

Electronic Boost Controller Comparison Chart

For a long time I’ve been wondering about the differences between the Rx-7 sequential twins and the Supra sequential twins. Both systems were originally designed for luxury cars (Mazda Cosmo and Toyota Aristo/Lexus GS) and then adapted for sports car use. So are the 2JZ sequential turbos simpler than the 13B/20B sequential turbos? Are they inherently more reliable? Having developed the 2JZ turbo system after Mazda, what did Toyota do differently and did Mazda “miss” something in their system design that Toyota figured out later?

To answer these questions, I searched through Mazda and Toyota technical papers on the respective engines. I searched though technician training/service highlights documents. I looked through workshop manuals and websites. I also physically examined the actual components in-person.

The Short Answer

Both systems have the exact same number of actuators and each actuator has basically the same overall purpose. The 2JZ has fewer solenoids and less plumbing compared to the 20B/13B design, while the actuators themselves are simpler. The 2JZ sequential twins are hardly bulletproof but they do have less failure points. However, the design of the 2JZ sequential turbo system inherently requires more space, and thus its architecture may not have even been possible with the packaging constraints of the Rx-7 and Cosmo.

Overview of how each engine's turbo system works

I know this is going to be hard to follow, but here is the basic idea of how the 13B-REW twin turbos work. As the driver starts from low rpm all exhaust gas flows into the primary turbocharger. As rpm increases and boost begins to reach a predetermined level, exhaust is diverted away through a small valve upstream of the secondary turbo. This valve regulates boost while allowing gases from the exhaust manifold to feed the secondary turbo.

As the secondary turbo spins up, on the compressor side a valve prevents its pressurized air from entering the engine. Instead another valve in the Y-pipe diverts that compressed air back to the intake until the secondary turbo is fully ready. When it is time for both turbos to run together, yet another valve opens upstream of the secondary turbo exhaust housing in order to feed it as much exhaust gas as possible. The compressed air from the secondary turbo compressor outlet is then allowed to flow into the engine. Finally a wastegate becomes the sole means of controlling boost by diverting exhaust gas upstream of the primary turbo and out towards the downpipe. The basic operation of the secondary turbo is controlled by two valves upstream of the exhaust side, before the turbine inlet.

(Sequential Twin Turbo is the production system; conventional turbocharging is a benchmark from a prototype used in development)

#2

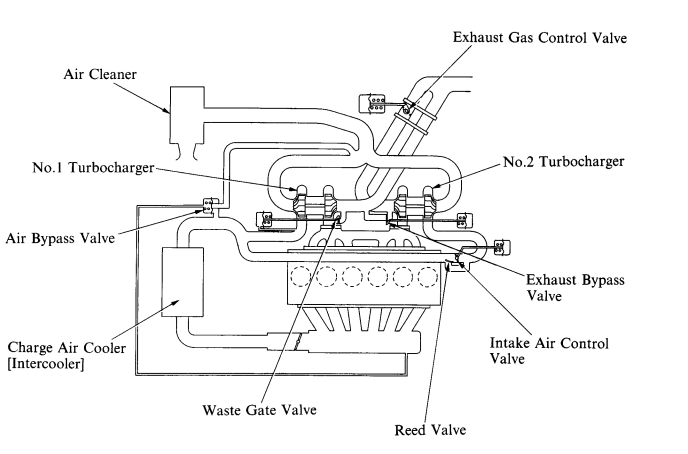

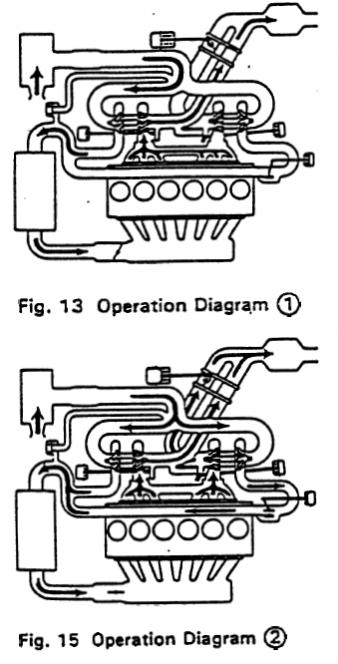

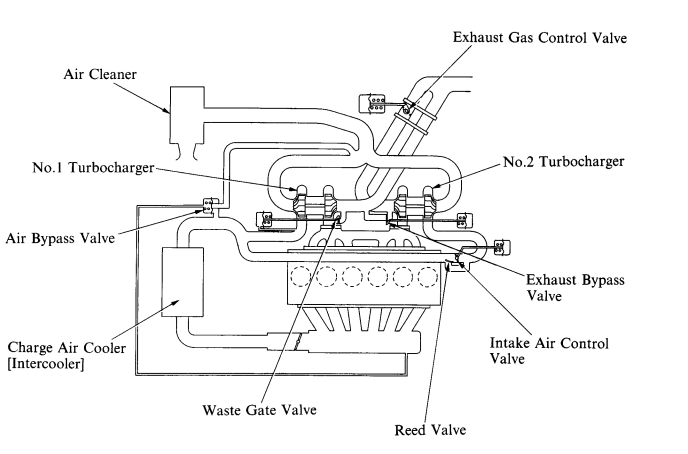

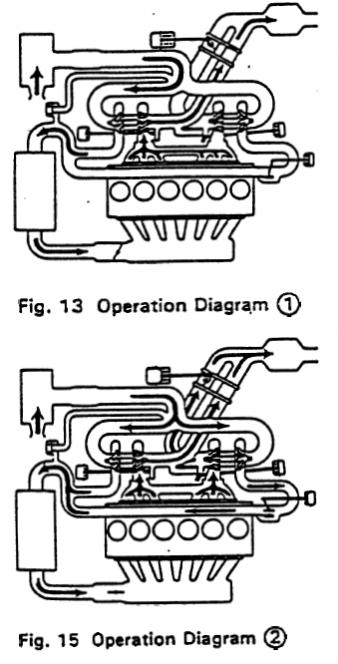

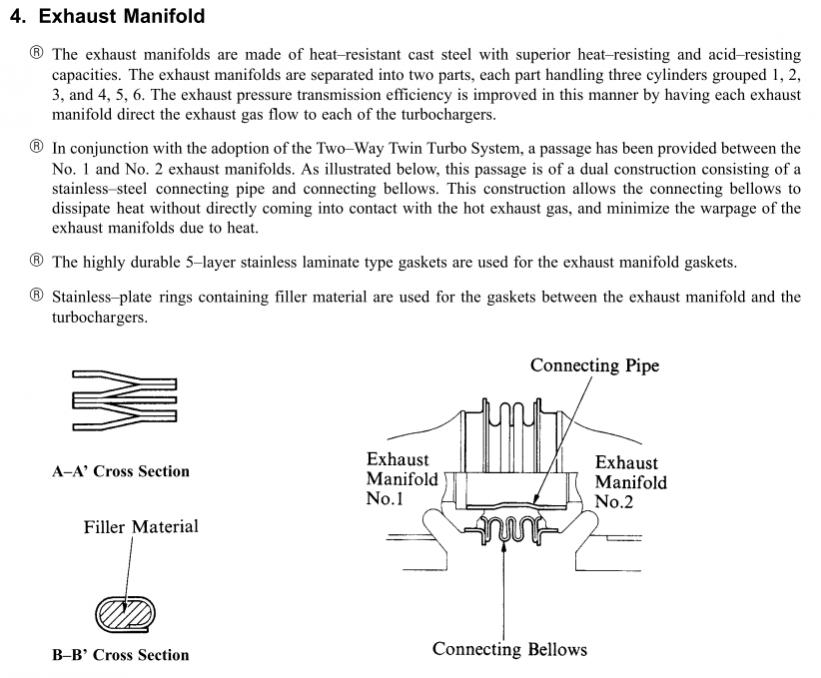

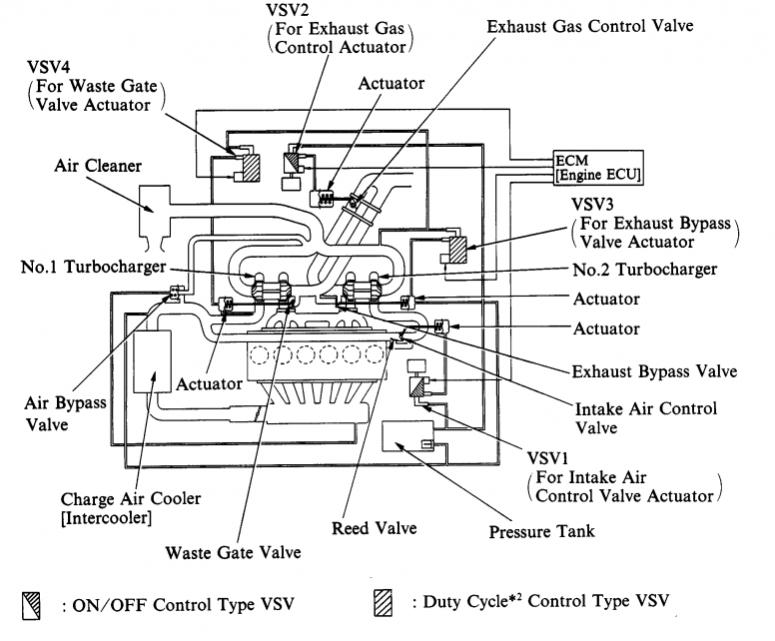

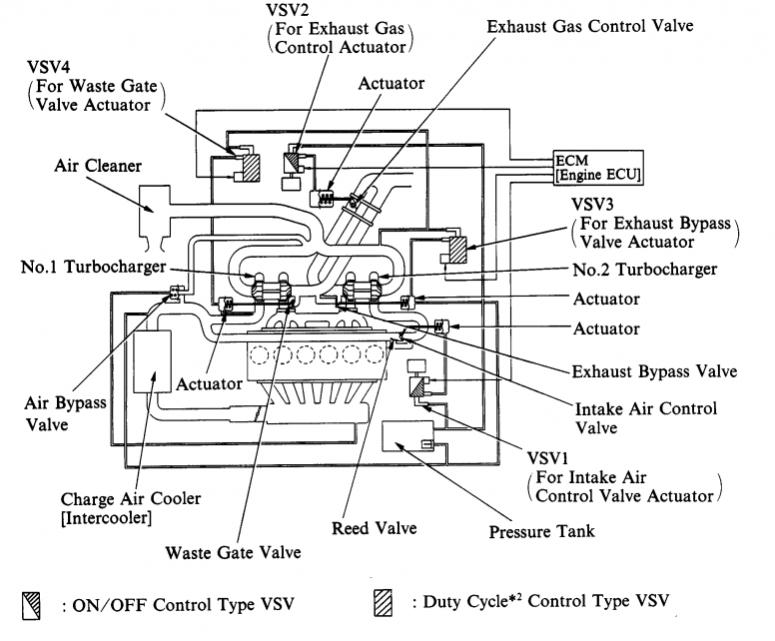

Here is the basic idea of how the 2JZ twin turbos work as the driver starts from low rpm. At first only the No. 1 turbo is active. The No. 2 turbo remains inactive by completely choking off the exhaust stream with two valves downstream of the No. 2 turbo. Unlike the 13B, on the 2JZ-GTE there are no valves upsteam of the No. 2 turbo to block exhaust from entering the turbine housing. As rpm increases and boost begins to reach a predetermined level, a small wastegate-sized passageway opens downstream of the No. 2 turbine housing. This valve controls boost because the wastegate is still closed. Some exhaust can now flow out of the No. 2 turbo and the turbo will begin to spin up. As the No. 2 turbo spins up, on the compressor side a valve prevents its pressurized air from entering the engine. At the predetermined time, a second and larger valve downstream of the No. 2 turbine housing opens up to allow full exhaust flow from the turbine housing. The secondary turbo comes online completely, and pressurized air from the No. 2 turbo is then allowed to enter the engine.

Note that unlike Mazda’s system, the 2JZ engine’s No. 2 turbo compressor side is never vented back to the airbox during prespool. This implies that the No. 2 turbo intentionally compressor surges during prespool—it builds boost bu the air has nowhere to go. This compressor surge continues until its boost pressure exceeds that of the No. 1 turbo and a valve opens in the intercooler piping. I know this whole compressor surge part is hard to understand and on its face completely counter-intuitive. However according to the literature Mazda engineers carefully engineered the REW sequential turbo system to also intentionally run in surge during prespool. As far as I know this has not been confirmed in real-world testing on production rotary cars.

The basic operation of the No. 2 turbo is controlled by two valves downstream of the turbo, after the turbine inlet in what we would normally consider the path of the exhaust.

(Two-Way Twin Turbo means the 2JZ sequential system, twin turbo is non sequential twins as used in the 1JZ engine)

Note that unlike Mazda’s system, the 2JZ engine’s No. 2 turbo compressor side is never vented back to the airbox during prespool. This implies that the No. 2 turbo intentionally compressor surges during prespool—it builds boost bu the air has nowhere to go. This compressor surge continues until its boost pressure exceeds that of the No. 1 turbo and a valve opens in the intercooler piping. I know this whole compressor surge part is hard to understand and on its face completely counter-intuitive. However according to the literature Mazda engineers carefully engineered the REW sequential turbo system to also intentionally run in surge during prespool. As far as I know this has not been confirmed in real-world testing on production rotary cars.

The basic operation of the No. 2 turbo is controlled by two valves downstream of the turbo, after the turbine inlet in what we would normally consider the path of the exhaust.

(Two-Way Twin Turbo means the 2JZ sequential system, twin turbo is non sequential twins as used in the 1JZ engine)

#3

Actuator Comparison

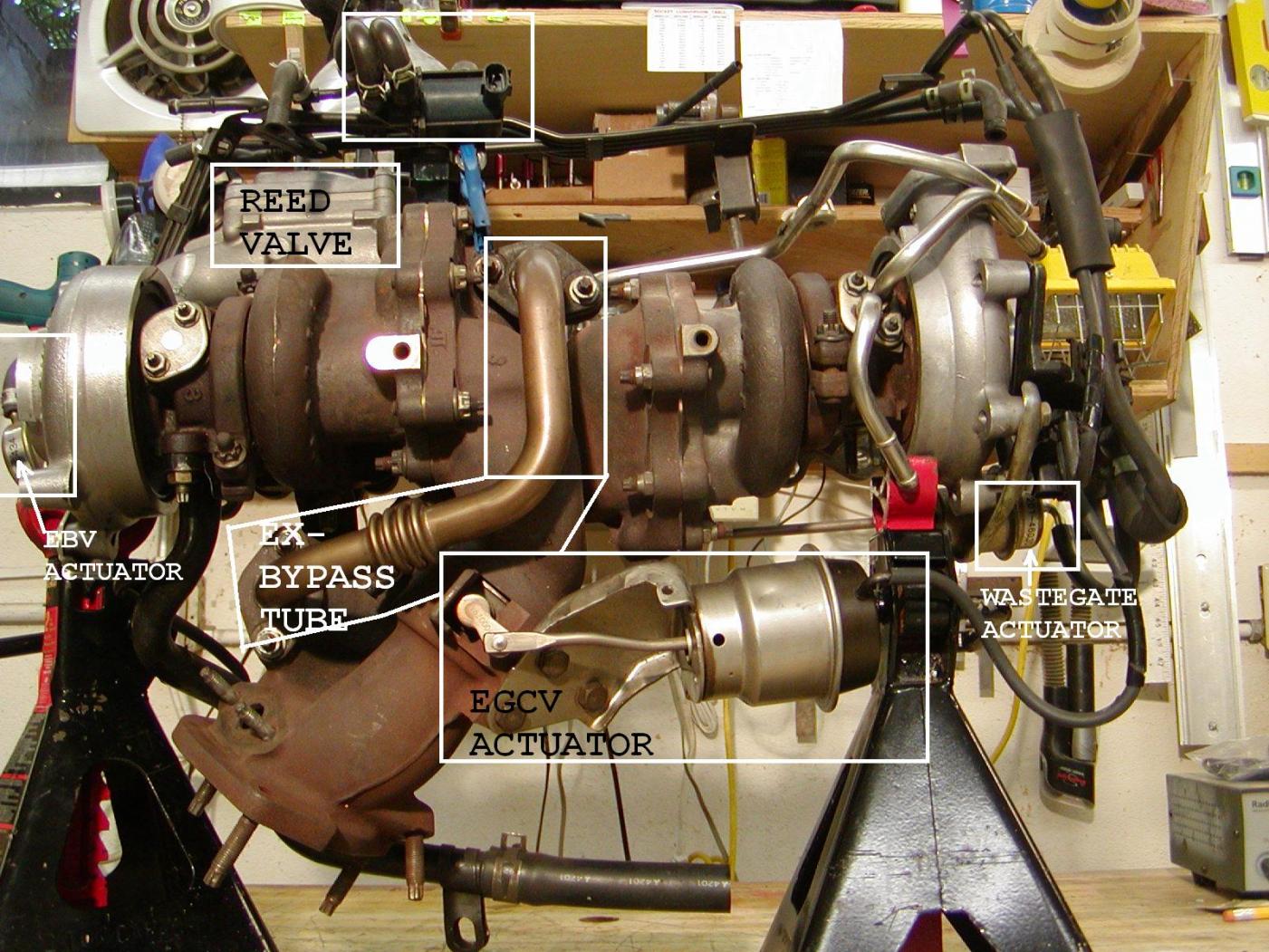

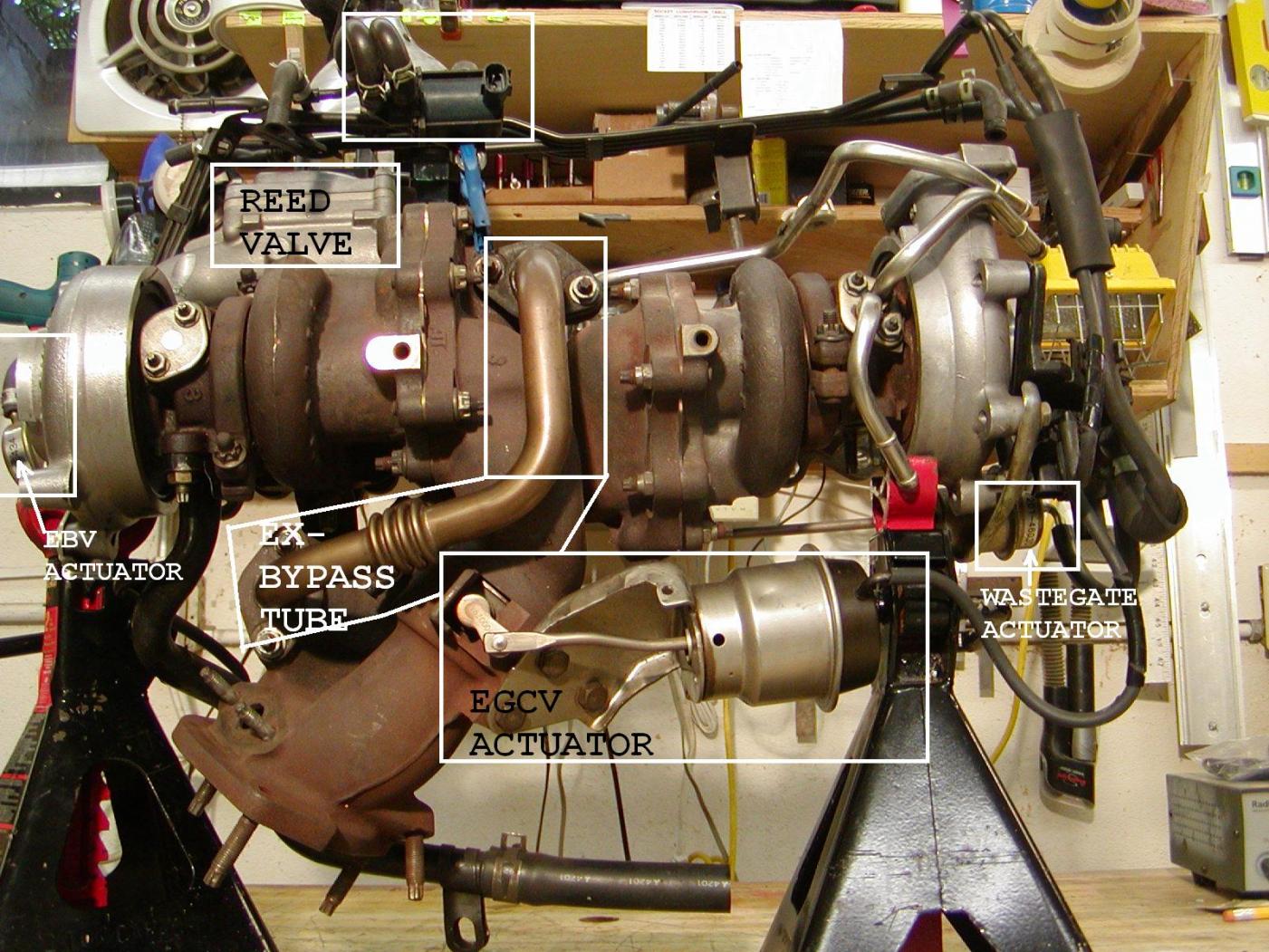

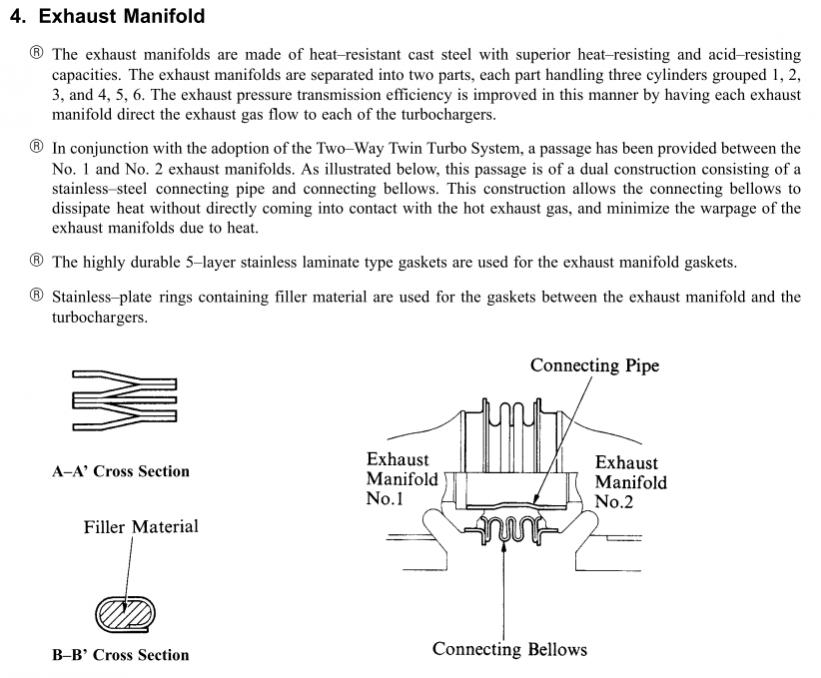

Here is a pic sourced from 97supraturbo.com showing the 2JZ turbo system and most of its actuators:

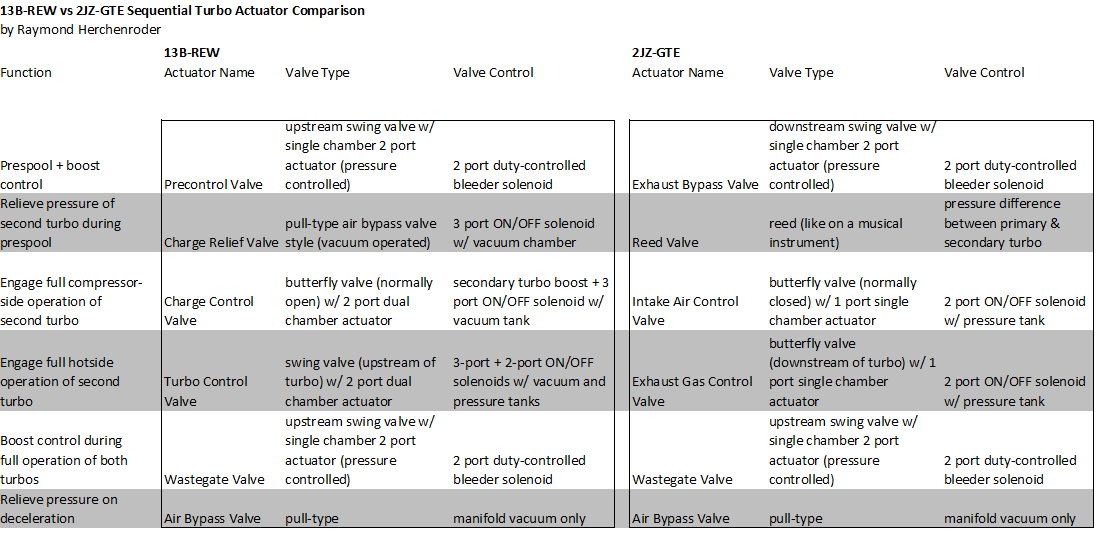

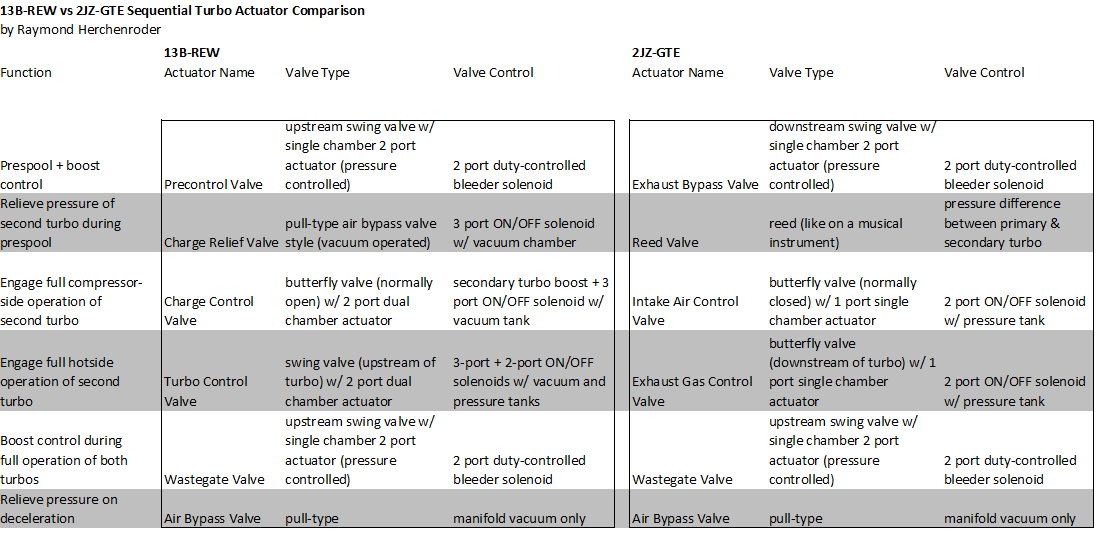

I have created a chart which compares each actuator used on both systems:

That is a very detailed and comprehensive chart with more information than most people are interested in. So here are the most important differences in actuator design. Note that all of the 2JZ’s main actuators for sequential turbo control run only on pressure; there are no vacuum-controlled actuators.

1) On the 2JZ, the big valve controlling the exhaust side of the No. 2 turbo is called the Exhaust Gas Control Valve. This is a butterfly valve (like a throttle plate) downstream of the turbo which chokes off exhaust flow. Toyota’s implementation of this design requires more space than what Mazda used for the same purpose. On the REW engines, the equivalent valve called the Turbo Control Valve is like a big wastegate flapper. It lies upstream of the turbo and chokes off the feed gases. The REW’s actuator requires both pressure and vacuum to operate.

2) On the 2JZ, the small valve controlling prespool is called the Exhaust Bypass Valve. It lies downstream of the turbo and in its normal closed position it chokes off exhaust flow. When this valve opens, a small amount of exhaust flows out from the No. 2 turbo through a small separate pipe so it can join the exhaust stream of the No. 1 turbo. Toyota’s implementation of this design requires more space than the design Mazda used to accomplish control of prespool using the REW’s precontrol valve. Just like the Precontrol Valve on the REW engines, the Exhaust Bypass Valve controls boost until both turbos come online. On both the Toyota and Mazda systems the valve and actuator are controlled like a wastegate.

3) On the 2JZ, during prespool the No. 2 turbo’s pressurized air does not flow back to the airbox like on the REW engines. During prespool the Reed Valve (as in a reed for a musical instrument) allows the No. 2’s pressurized air to enter the engine by going around the closed Intake Air Control valve. The pressure from the No. 2 turbo must exceed the pressure from the No. 1 turbo for the Reed Valve to open. Diagram of the reed valve:

Here is a pic sourced from 97supraturbo.com showing the 2JZ turbo system and most of its actuators:

I have created a chart which compares each actuator used on both systems:

That is a very detailed and comprehensive chart with more information than most people are interested in. So here are the most important differences in actuator design. Note that all of the 2JZ’s main actuators for sequential turbo control run only on pressure; there are no vacuum-controlled actuators.

1) On the 2JZ, the big valve controlling the exhaust side of the No. 2 turbo is called the Exhaust Gas Control Valve. This is a butterfly valve (like a throttle plate) downstream of the turbo which chokes off exhaust flow. Toyota’s implementation of this design requires more space than what Mazda used for the same purpose. On the REW engines, the equivalent valve called the Turbo Control Valve is like a big wastegate flapper. It lies upstream of the turbo and chokes off the feed gases. The REW’s actuator requires both pressure and vacuum to operate.

2) On the 2JZ, the small valve controlling prespool is called the Exhaust Bypass Valve. It lies downstream of the turbo and in its normal closed position it chokes off exhaust flow. When this valve opens, a small amount of exhaust flows out from the No. 2 turbo through a small separate pipe so it can join the exhaust stream of the No. 1 turbo. Toyota’s implementation of this design requires more space than the design Mazda used to accomplish control of prespool using the REW’s precontrol valve. Just like the Precontrol Valve on the REW engines, the Exhaust Bypass Valve controls boost until both turbos come online. On both the Toyota and Mazda systems the valve and actuator are controlled like a wastegate.

3) On the 2JZ, during prespool the No. 2 turbo’s pressurized air does not flow back to the airbox like on the REW engines. During prespool the Reed Valve (as in a reed for a musical instrument) allows the No. 2’s pressurized air to enter the engine by going around the closed Intake Air Control valve. The pressure from the No. 2 turbo must exceed the pressure from the No. 1 turbo for the Reed Valve to open. Diagram of the reed valve:

#4

Advantages of the 2JZ Sequential Turbo System

The 2JZ’s sequential turbo system has the following advantages compared to the system used in the REW engines:

1) Fewer and simpler solenoids – the 2JZ uses four 2-port solenoids. When I say 2-port solenoid, think about the stock wastegate and precontrol solenoids on the REW engines. The REW engines uses three 2-port and three 3-port solenoids. By 3 port solenoids I am referring ot the solenoids found in the rat’s nest. In my personal experience I see 2-port solenoids fail less often than 3-port.

2) No vacuum chamber and no separate check valves are used for the 2JZ turbo system. The 2JZ has a pressure chamber with presumably an integrated check valve. While this tank does leak sometimes, overall there are less failure points in the system.

3) Fewer vacuum lines -- fewer solenoids and simpler actuators require fewer hoses to control.

Conclusion - Why Didn’t Mazda Use the 2JZ’s system design?

Mazda designed their sequential system in late 1980’s originally for the Cosmo luxury coupe. This was after the sequentially turbocharged Porsche 959 supercar but before the Toyota Aristo/Lexus GS and Subaru’s twin turbo Liberty/Legacy. When Mazda was developing their system, Sequential twin turbos had never been done in a mass production car so they had very little real-world data on reliability. For cost savings Mazda had to adapt or re-use existing parts and systems. Some of the vacuum systems and actuators had clearly been modified from the older rotary engines. Mazda appears to have used off-the-shelf 3 port vacuum solenoids—they just added to the rat’s nest found in previous generation rotary engines.

So why didn’t Mazda use Toyota’s design and control the secondary turbo after the turbine outlet instead of before the turbine inlet? Part of the exhaust side of the REW turbo system came from modifying the variable turbine A/R system used on 86-88 model turbo 13B engines, which allowed for cost savings. Using a Toyota-style system may have been more reliable because it has simpler plumbing. The chief disadvantage I see of the 2JZ’s system is packaging. The Exhaust Bypass Valve, Exhaust Gas Control valve, and their associated exhaust piping require more space than Mazda’s compact Precontrol Valve and Turbo Control valve. Rotary-powered cars usually have the engine mounted low and behind the front axle so little space is available. Mazda already had to carefully shape the lower intake manifold on the Rx-7 13B-REW to fit the turbos.

Looking back at it, for the series 6 Rx-7 the engineers did the best they could given their many constraints. They had to use the turbo system that had already been developed for the Cosmo. The revised solenoid rack on later engines supposedly helped reliability but the new parts still failed over time due to other underlying issues such as heat. With the cancellation of the Cosmo and the failure of the Rx-7 to achieve commercial success Mazda would not devote much money to making the turbo system more reliable. The 90s are long over now; on modern gasoline engines twin turbos are coming back but sequential turbo systems are conspicuously absent from these new downsized engines. This is due to the cost and complexity inherent in systems like the ones described in this article.

References

Akihito, Development of Toyota JZ Type Engine Series, 1993

Mazda 1993 Rx-7 Service Highlights document

Tashima, Sequential Twin Turbocharged Rotary Engine of the Latest Rx-7, 1994

Tashima, Development of Sequential Twin Turbo System for Rotary Engine, 1991

Toyota 1993 Supra New Features document

www.97supraturbo.com

If you actually read through all that, you deserve a

The 2JZ’s sequential turbo system has the following advantages compared to the system used in the REW engines:

1) Fewer and simpler solenoids – the 2JZ uses four 2-port solenoids. When I say 2-port solenoid, think about the stock wastegate and precontrol solenoids on the REW engines. The REW engines uses three 2-port and three 3-port solenoids. By 3 port solenoids I am referring ot the solenoids found in the rat’s nest. In my personal experience I see 2-port solenoids fail less often than 3-port.

2) No vacuum chamber and no separate check valves are used for the 2JZ turbo system. The 2JZ has a pressure chamber with presumably an integrated check valve. While this tank does leak sometimes, overall there are less failure points in the system.

3) Fewer vacuum lines -- fewer solenoids and simpler actuators require fewer hoses to control.

Conclusion - Why Didn’t Mazda Use the 2JZ’s system design?

Mazda designed their sequential system in late 1980’s originally for the Cosmo luxury coupe. This was after the sequentially turbocharged Porsche 959 supercar but before the Toyota Aristo/Lexus GS and Subaru’s twin turbo Liberty/Legacy. When Mazda was developing their system, Sequential twin turbos had never been done in a mass production car so they had very little real-world data on reliability. For cost savings Mazda had to adapt or re-use existing parts and systems. Some of the vacuum systems and actuators had clearly been modified from the older rotary engines. Mazda appears to have used off-the-shelf 3 port vacuum solenoids—they just added to the rat’s nest found in previous generation rotary engines.

So why didn’t Mazda use Toyota’s design and control the secondary turbo after the turbine outlet instead of before the turbine inlet? Part of the exhaust side of the REW turbo system came from modifying the variable turbine A/R system used on 86-88 model turbo 13B engines, which allowed for cost savings. Using a Toyota-style system may have been more reliable because it has simpler plumbing. The chief disadvantage I see of the 2JZ’s system is packaging. The Exhaust Bypass Valve, Exhaust Gas Control valve, and their associated exhaust piping require more space than Mazda’s compact Precontrol Valve and Turbo Control valve. Rotary-powered cars usually have the engine mounted low and behind the front axle so little space is available. Mazda already had to carefully shape the lower intake manifold on the Rx-7 13B-REW to fit the turbos.

Looking back at it, for the series 6 Rx-7 the engineers did the best they could given their many constraints. They had to use the turbo system that had already been developed for the Cosmo. The revised solenoid rack on later engines supposedly helped reliability but the new parts still failed over time due to other underlying issues such as heat. With the cancellation of the Cosmo and the failure of the Rx-7 to achieve commercial success Mazda would not devote much money to making the turbo system more reliable. The 90s are long over now; on modern gasoline engines twin turbos are coming back but sequential turbo systems are conspicuously absent from these new downsized engines. This is due to the cost and complexity inherent in systems like the ones described in this article.

References

Akihito, Development of Toyota JZ Type Engine Series, 1993

Mazda 1993 Rx-7 Service Highlights document

Tashima, Sequential Twin Turbocharged Rotary Engine of the Latest Rx-7, 1994

Tashima, Development of Sequential Twin Turbo System for Rotary Engine, 1991

Toyota 1993 Supra New Features document

www.97supraturbo.com

If you actually read through all that, you deserve a

#5

Batman

Join Date: Jun 2011

Location: Tasmania, Australia

Posts: 53

Likes: 0

Received 0 Likes

on

0 Posts

Thats pretty awesome stuff. So basically the toyota and mazda engineers specifically designed the system so that the secondary turbo would run in surge conditions before it comes online. Difference being that the mazda secondary vents to the airbox, whereas the 2JZ secondary does not, which means there could be some reversion stuff going on in the 2JZ's secondary compressor wheel housing during prespool. If I've got that right.

I'm not so much interested in the actuators as much as the way the system spools.

I know on a standard REW if you release the throttle during primary + secondary operation and the revs dip before you put your foot back in, there's a noticeable lag because you've got lower revs, yet both turbos are online, and both need to be spooled back up, which takes some time for the system to play catch up

I'm not so much interested in the actuators as much as the way the system spools.

I know on a standard REW if you release the throttle during primary + secondary operation and the revs dip before you put your foot back in, there's a noticeable lag because you've got lower revs, yet both turbos are online, and both need to be spooled back up, which takes some time for the system to play catch up

#7

So basically the toyota and mazda engineers specifically designed the system so that the secondary turbo would run in surge conditions before it comes online. Difference being that the mazda secondary vents to the airbox, whereas the 2JZ secondary does not, which means there could be some reversion stuff going on in the 2JZ's secondary compressor wheel housing during prespool.

On the Supra, the No. 2 turbo builds boost and there is no way to vent the air back to the airbox. There is no charge relief valve and no charge relief solenoid. A local shop recently had a mint 2JZ they had just imported out of Japan from a very low mileage Supra. I was over there looking at it while it was still on the pallet. I kept scratching my head--where the hell is the charge relief valve? How does that work??

It was only when I consulted the literature that it made sense. Although it's not stated explicitly Toyota's paper, the No. 2 turbo always runs in surge during spoolup by the simple fact that there is nowhere for the air to go. Once the boost pressure gets high enough, it will push open the reed valve in the intercooler piping. The air will bypass the Supra's equivalent of the charge control valve which would be closed at the time. The No. 2 turbo's air will be entering the engine by going around that closed valve (intake air control valve, known as the charge control valve on a rotary).

It's really strange stuff. I never would have guessed. It also took me a while to understand that the exhaust side is controlled downstream of the turbo. It just didn't seem like it would work.

Trending Topics

#9

Radioactive Rotary Rocket

Join Date: Aug 2005

Location: Minneapolis, MN

Posts: 1,061

Likes: 0

Received 0 Likes

on

0 Posts

Wow thanks for giving us the opportunity to understand this. I don't know that many people that can explain how this works beyond the simple "there's two turbos" explanation.

I thought it was really interesting that this system is actually older than the twin turbo subaru legacy system.

I thought it was really interesting that this system is actually older than the twin turbo subaru legacy system.

#10

From what I can see, the Porsche 959 system came out first. Then the Cosmo 20B and 13B sequential turbo systems came out. The FD sequential turbo system followed; it is basically the same as the Cosmo 13B (13B-RE) although the turbos are different. The Subaru Liberty/Legacy sequential twin turbo system came to market at about the same time that Toyota started selling the 2JZ-GTE.

I have been unable to find any useful information on how the Porsche 959 or Subaru Legacy systems actually work. A lack of info on the Porsche 959 doesn't surprise me considering how few were made. There are still plenty of sequential twin turbo Liberty/Legacy models around (except in the USA of course) but I can't find any manuals or anything. Subaru tuners hate the sequential system and from what I can see basically nobody understands it. When modding that engine Subaru tuners are very quick to go single--the Subaru sequential system has a reputation for very bad boost drop during turbo transition. This is probably because something failed and nobody has a clue how to troubleshoot due to poor documentation. Rx-7 owners are lucky that Mazda documented the sequential turbo system so well. The service manual and service highlights explain enough that you can narrow down the problems. Information on the Supra system is a little spottier but luckily it's less complicated than what Mazda uses.

Just FYI,

Cosmo 20B: Primary turbo is Hitachi HT15, secondary turbo is Hitachi HT10

Cosmo 13B: Primary and secondary turbo are both HT10

Rx-7 13B: Primary and secondary turbo are both HT12

I believe both the Supra and Aristo use CT12 turbos but I could be wrong. If you look at manufacturer dyno curves, the Aristo is tuned for more low end torque since it is a luxury car. The Aristo twin turbos have ceramic compressor wheels (Supra does not), which was a popular thing for high-end Japanese turbo cars in the 90s.

I have been unable to find any useful information on how the Porsche 959 or Subaru Legacy systems actually work. A lack of info on the Porsche 959 doesn't surprise me considering how few were made. There are still plenty of sequential twin turbo Liberty/Legacy models around (except in the USA of course) but I can't find any manuals or anything. Subaru tuners hate the sequential system and from what I can see basically nobody understands it. When modding that engine Subaru tuners are very quick to go single--the Subaru sequential system has a reputation for very bad boost drop during turbo transition. This is probably because something failed and nobody has a clue how to troubleshoot due to poor documentation. Rx-7 owners are lucky that Mazda documented the sequential turbo system so well. The service manual and service highlights explain enough that you can narrow down the problems. Information on the Supra system is a little spottier but luckily it's less complicated than what Mazda uses.

Just FYI,

Cosmo 20B: Primary turbo is Hitachi HT15, secondary turbo is Hitachi HT10

Cosmo 13B: Primary and secondary turbo are both HT10

Rx-7 13B: Primary and secondary turbo are both HT12

I believe both the Supra and Aristo use CT12 turbos but I could be wrong. If you look at manufacturer dyno curves, the Aristo is tuned for more low end torque since it is a luxury car. The Aristo twin turbos have ceramic compressor wheels (Supra does not), which was a popular thing for high-end Japanese turbo cars in the 90s.

#11

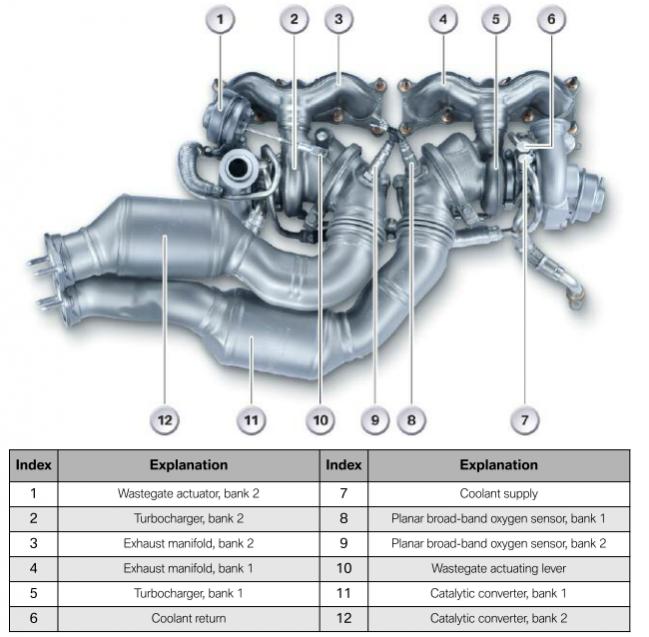

Some of you may be curious about the 2JZ-GTE's exhaust manifolds. The 2JZ uses a double-layered cast steel design with a flex pipe to reduce stress.

The old 1JZ non sequential twins for the JZA70 Mark III Supra had two separate cast iron pieces, each for a set of 3 cylinders. The FD uses a thick cast iron exhaust manifold with a flapper built in for the Turbo Control Valve.

This manifold is more compact than the 2JZ manifold. Part of that is due to the simple fact that 2 rotor engine is smaller than an inline 6. The other reason is that the FD exhaust manifold was clearly adapted from older turbo rotary exhaust manifolds. Here is the series 5 Rx-7 exhaust manifold which is divided:

Here is the series 4 which is undivided and has a flapper on it for the variable turbine A/R system:

Here is the series 3 manifold for the 12A turbo engine which has a very basic collected design:

The old 1JZ non sequential twins for the JZA70 Mark III Supra had two separate cast iron pieces, each for a set of 3 cylinders. The FD uses a thick cast iron exhaust manifold with a flapper built in for the Turbo Control Valve.

This manifold is more compact than the 2JZ manifold. Part of that is due to the simple fact that 2 rotor engine is smaller than an inline 6. The other reason is that the FD exhaust manifold was clearly adapted from older turbo rotary exhaust manifolds. Here is the series 5 Rx-7 exhaust manifold which is divided:

Here is the series 4 which is undivided and has a flapper on it for the variable turbine A/R system:

Here is the series 3 manifold for the 12A turbo engine which has a very basic collected design:

#14

thanks alot for the very useful information!!Have you checked the sequential system that the bmw uses to the 3 coupe series?that would be an interesting comparison between the past and now....

#15

The 1JZ has separate cast iron manifolds and a twin turbo assembly that bolts to them.

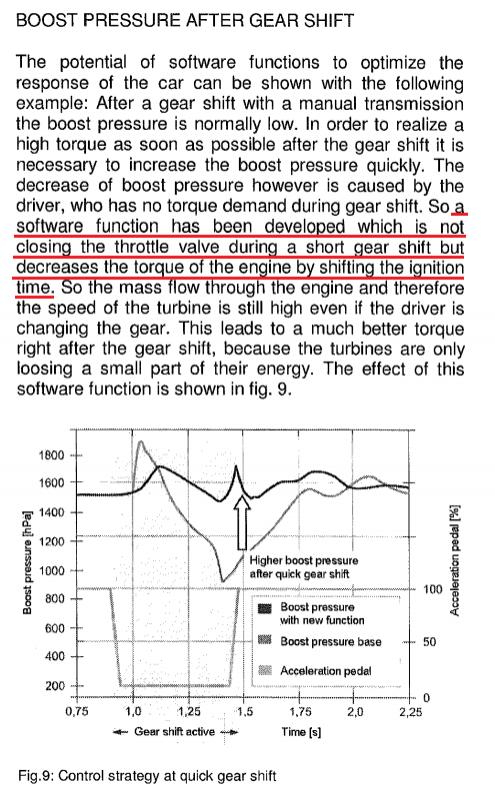

These use traditional wastegate actuators that run on pressure. In contrast the N54 has the turbo manifold and turbine side all manufactured as a single piece for each turbo, a common design these days. It also uses true dual exhaust and dual converters for better emissions. Exhaust temperatures can get extremely hot, up to 1050C/1900F which is as hot or perhaps hotter than a rotary engine typically gets to.

The wastegates are vacuum operated instead of pressure operated. A vacuum pump is used to generate the necessary vacuum. This allows the wastegate to be controlled under all conditions and thus wastegate valve control is not constrained by gate spring pressure in the same way. This allows the gates to be optimized for fuel economy or spool depending on the calibration. The N54 also integrates an antilag system into the electronic throttle control to minimize boost drop off between shifts:

It's just the difference of about 20 years of development in engineering and manufacturing techniques.

#16

Very very informative read... I have a friend with 3 2JZ-GTE's one is for a track built Soarer, (HKS single) and the other two are stick and in Aristo's... After all that info, I'm confident to say I know more about his twins then he does... Lol

Thanks for taking the time to put that up... And in such simple terms too...

Props... (if this forum had Rep points, I would totally hit you up)

J.

Thanks for taking the time to put that up... And in such simple terms too...

Props... (if this forum had Rep points, I would totally hit you up)

J.

#17

So here's a vacuum routing diagram for a simplified sequential FD, with the colored lines showing the basic connections needed to operate the turbo system:

And here is a diagram of the Supra 2JZ sequential turbo system (excludes emissions stuff)

There are still noticeably less vacuum lines for the 2JZ system because there is no vacuum chamber and because there are fewer and simpler solenoids.

And here is a diagram of the Supra 2JZ sequential turbo system (excludes emissions stuff)

There are still noticeably less vacuum lines for the 2JZ system because there is no vacuum chamber and because there are fewer and simpler solenoids.

#19

That BMW system is for a manual transmission if you read carefully. Traditional automatics already hold boost during shifts. There are various aftermarket antilag systems used on manual transmissions, mostly on rally cars. The BMW design is on regular street cars and utilizes the electronic throttle system.

#20

I have debated this point in another thread. Nobody has definitively observed the surge on a rotary but the papers on the 20B and REW specifically described how the surge is induced. The surge is induced by deliberately turning off the charge relief valve and disabling this venting back to the airbox. The air builds up and has nowhere to go, creating surge and heating up the compressor wheel. Mazda carefully measured just how long they can run the secondary turbo in surge before it gets too hot. So the on the rotary engine the ECU has the capability to turn on or turn off the surging by the timing of the charge control and charge relief valve operation. On the Supra it is a completely mechanical control.

On the Supra, the No. 2 turbo builds boost and there is no way to vent the air back to the airbox. There is no charge relief valve and no charge relief solenoid. A local shop recently had a mint 2JZ they had just imported out of Japan from a very low mileage Supra. I was over there looking at it while it was still on the pallet. I kept scratching my head--where the hell is the charge relief valve? How does that work??

It was only when I consulted the literature that it made sense. Although it's not stated explicitly Toyota's paper, the No. 2 turbo always runs in surge during spoolup by the simple fact that there is nowhere for the air to go. Once the boost pressure gets high enough, it will push open the reed valve in the intercooler piping. The air will bypass the Supra's equivalent of the charge control valve which would be closed at the time. The No. 2 turbo's air will be entering the engine by going around that closed valve (intake air control valve, known as the charge control valve on a rotary).

It's really strange stuff. I never would have guessed. It also took me a while to understand that the exhaust side is controlled downstream of the turbo. It just didn't seem like it would work.

On the Supra, the No. 2 turbo builds boost and there is no way to vent the air back to the airbox. There is no charge relief valve and no charge relief solenoid. A local shop recently had a mint 2JZ they had just imported out of Japan from a very low mileage Supra. I was over there looking at it while it was still on the pallet. I kept scratching my head--where the hell is the charge relief valve? How does that work??

It was only when I consulted the literature that it made sense. Although it's not stated explicitly Toyota's paper, the No. 2 turbo always runs in surge during spoolup by the simple fact that there is nowhere for the air to go. Once the boost pressure gets high enough, it will push open the reed valve in the intercooler piping. The air will bypass the Supra's equivalent of the charge control valve which would be closed at the time. The No. 2 turbo's air will be entering the engine by going around that closed valve (intake air control valve, known as the charge control valve on a rotary).

It's really strange stuff. I never would have guessed. It also took me a while to understand that the exhaust side is controlled downstream of the turbo. It just didn't seem like it would work.

https://www.rx7club.com/10724277-post/

For reference:

What would happen if you took chamber B's inlet hose and attached it to the compressor side of the primary turbo and chamber A's inlet to the secondary's compressor side?

My guess is if pressure on the primary side exceeds that of the secondary, it forces the CCV to close, much like normal operation in which B(more pressure)->A(less pressure).

Once the secondary turbo builds enough boost (with the CRV closed and no where for the air to go), it will exceed the primary turbo side B(less pressure)->A(more pressure), and force the door to crack open.

I'm thinking at that point, the CCV may act more like the 2JZ's reed valve.

Last edited by NeoTuri; 12-08-11 at 09:00 PM.

#21

Turbo Lover

iTrader: (6)

Join Date: Feb 2003

Location: Cleveland

Posts: 783

Likes: 0

Received 0 Likes

on

0 Posts

What I'm curious about is how the REW twins use a single wastegate in the primary turbo to control the boost for both turbos. Wouldn't that mean that the engine is being choked?

Once full boost is reached, the primary turbo has to handle the majority of the exhaust being delivered by both rotors. As in, excess exhaust that can't go into the rear turbo has to then travel through the manifold and into the front turbo. Wouldn't making the front turbo handle all this extra exhaust effectively choke the motor?

Obviously the system works under stock boost pressures, but many members run much higher then stock pressures. So I guess I'm asking these questions in the context of running high boost on the twins.

Once full boost is reached, the primary turbo has to handle the majority of the exhaust being delivered by both rotors. As in, excess exhaust that can't go into the rear turbo has to then travel through the manifold and into the front turbo. Wouldn't making the front turbo handle all this extra exhaust effectively choke the motor?

Obviously the system works under stock boost pressures, but many members run much higher then stock pressures. So I guess I'm asking these questions in the context of running high boost on the twins.

#22

What would happen if you took chamber B's inlet hose and attached it to the compressor side of the primary turbo and chamber A's inlet to the secondary's compressor side?

My guess is if pressure on the primary side exceeds that of the secondary, it forces the CCV to close, much like normal operation in which B(more pressure)->A(less pressure).

Once the secondary turbo builds enough boost (with the CRV closed and no where for the air to go), it will exceed the primary turbo side B(less pressure)->A(more pressure), and force the door to crack open.

I'm thinking at that point, the CCV may act more like the 2JZ's reed valve.

My guess is if pressure on the primary side exceeds that of the secondary, it forces the CCV to close, much like normal operation in which B(more pressure)->A(less pressure).

Once the secondary turbo builds enough boost (with the CRV closed and no where for the air to go), it will exceed the primary turbo side B(less pressure)->A(more pressure), and force the door to crack open.

I'm thinking at that point, the CCV may act more like the 2JZ's reed valve.

The 2JZ's Reed valve is a completely mechanical design and must have been carefully optimized for the system. I suspect Mazda at least evaluated using a simpler control of the charge control valve such as what you have described but chose to go with solenoid control.

I think it just comes down to the fact that the single wastegate design got the job done with better packaging efficiency and cost reduction than a dual wastegate design.

Once full boost is reached, the primary turbo has to handle the majority of the exhaust being delivered by both rotors. As in, excess exhaust that can't go into the rear turbo has to then travel through the manifold and into the front turbo. Wouldn't making the front turbo handle all this extra exhaust effectively choke the motor?

Obviously the system works under stock boost pressures, but many members run much higher then stock pressures. So I guess I'm asking these questions in the context of running high boost on the twins.

#23

The overall idea you are describing is another possible way to utilize the dual diaphragm chamber design. There's nothing unusual about a dual diaphragm chamber; an external wastegate is a good example of one. The thing about what you are proposing is that the actuator would have to be specifically designed for it in terms of the stiffness of the spring and such. It would be mechanically simpler but you then lose computer control via the solenoid.

The 2JZ's Reed valve is a completely mechanical design and must have been carefully optimized for the system. I suspect Mazda at least evaluated using a simpler control of the charge control valve such as what you have described but chose to go with solenoid control.

The 2JZ's Reed valve is a completely mechanical design and must have been carefully optimized for the system. I suspect Mazda at least evaluated using a simpler control of the charge control valve such as what you have described but chose to go with solenoid control.

Now I'm curious. If Mazda knew the length of time the secondary could turbo boost into a blocked airway before it burns up and was able to delay the CCV from opening after the CRV closes, then that could explain why two solenoids are necessary. That would also mean the opened/closed states of the CCV and CRV are not mutually exclusive. This is not exactly news, but it does add an element of finesse that the vacuum diagram does not.

#24

Full Member

Join Date: Oct 2011

Location: Wilmington, NC

Posts: 220

Likes: 0

Received 0 Likes

on

0 Posts

On my wife's FD the Previsous owner removed and blocked off the charge reieif valve. I can't find one for sale. what would be the best thing to do about it. i ran the line back to into the manifold. should i just leave it blocked off and on like the 2jz?