Boost control problem

#1

Where does this bolt go?

Thread Starter

iTrader: (8)

Join Date: Oct 2008

Location: TN

Posts: 315

Likes: 0

Received 0 Likes

on

0 Posts

Boost control problem

I am having a boost control problem with my Blitz DSBC spec r. I have a 93 R1 with an A-spec GT35R running a Tial 44 with a .9 bar spring. I currently am running on spring pressure only which gives me a solid 14psi, but I would like to get my boost controller working. I bought the boost controller used from a forum member and have read the instructions and any post related to it. I have 6mm hose feeding the side port on the wastegate from the elbow off the compressor housing. This is also connected to a T with the other line to the in port on the solenoid and out to the top port on the Tial. My hose lengths are under 3 feet and routed so there are no kinks in the lines. The Blitz control unit gets its pressure source from the uim just behind the throttle plates. I used a hard plastic mechanical gauge line to feed the control unit. The control unit sees the boost correctly and gives similar readings as the boost gauge and pfc. Now to the problem, It wont control boost. I have set the controller to 0 gain and 0 volume and still get boost past 16psi. I have tried it with the controller set to off and it still climbs past 16psi. When I hit the boost warning limit it will cut boost hard so I know it is capable of controlling boost. When I say it climbs past 16psi, I mean it will go until I let off or its hits the boost limit warning. I have the switch set to wg on the back and have tested the solenoids. When I set the controller to off and I pressurize the system to about 2 psi, the solenoids will open and allow pressure to vent to atmosphere. I would think this should allow for spring pressure to take over but it doesn't work. I have also tested with low boost settings on 1 and it seems to trigger the solenoids at the proper pressure when manually testing the system. Any Ideas.

1. Do you think using a T could be the problem? I have a barbed fitting screwed into the elbow off the compressor housing. It has about 2 inches of 6mm hose going to a T and then one hose going to the side of the wastegate and the other hose going to the boost solenoid.

2. Do you think it could be the feed line going to the control unit? Too small?

1. Do you think using a T could be the problem? I have a barbed fitting screwed into the elbow off the compressor housing. It has about 2 inches of 6mm hose going to a T and then one hose going to the side of the wastegate and the other hose going to the boost solenoid.

2. Do you think it could be the feed line going to the control unit? Too small?

#4

Where does this bolt go?

Thread Starter

iTrader: (8)

Join Date: Oct 2008

Location: TN

Posts: 315

Likes: 0

Received 0 Likes

on

0 Posts

Probably. The solenoid box has 2 solenoids inside which look like stock FD solenoids. They are paired by a rubber manifold and the upper most port is vented to atmosphere. I have tested the solenoids with a meter and an external pressure source and only one solenoid will operate at a time. I can switch the connectors on the solenoids and make the the other solenoid work, but not both at the same time. I am wondering if it needs both solenoids venting to handle the large amount of air coming through the feed line.

#5

a pic of the assembly would be nice (preferably marked up in MS paint to show things). What you are describing is not a standard 3 way solenoid that is used in most aftermarket boost control systems. It sounds like you have a two-way NC (normally closed) solenoid like the factory wastegate solenoid, and a two-way NO (normally open) solenoid, which is not too far from the factory boost control solenoid on the series 5 FC turbo cars.

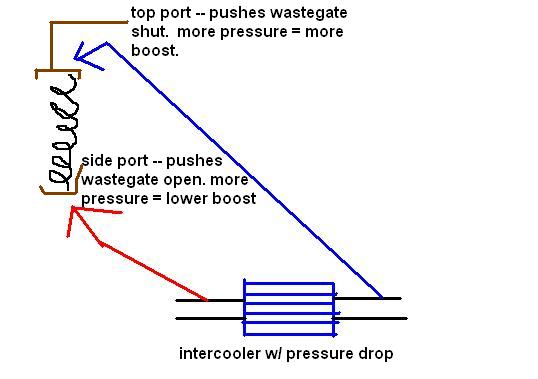

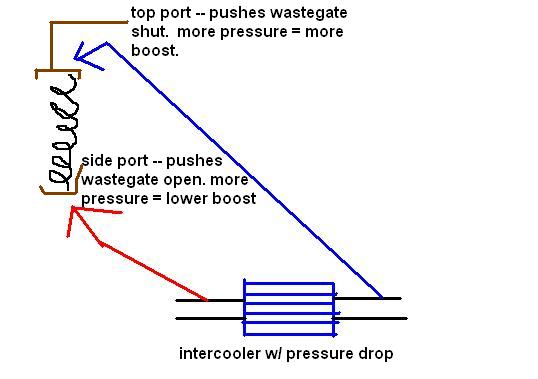

Recall this diagram:

On an external wastegate with the usual plumbing configuration, the more air that passes through that solenoid the more your boost will increase as it pressurizes the top port of the wastegate. That is why external wastegates use Normally Closed (aka "NC" type) solenoids. When I pressurize the factory NC wastegate solenoid (with it off), I can literally pump it up to 60psi until the hose blows off. No air will pass through at all if the solenoid has not been engaged by the ECU or by me supplying voltage to the solenoid coil. No air should pass to the top port of an external wastegate with the solenoid off!

On an internally wastegated turbo (or on the side port of an external wastegate), the more air that passes through that solenoid the more your boost will DECREASE, with the minimum boost usually being the rated spring pressure. Those use solenoids in the Normally Open (NO) configuration. Air will always pass through them without 12V being applied. Then with 12V is applied, the solenoid will close and the pressure signal will be interrupted. If I'm reading what you are saying correctly, your solenoid behavior is more consistent with an internal wastegate setup.

You need to figure out how to plumb it so that with no voltage applied, no air passes through. When voltage is applied, air passes through, but some is vented out to atmosphere so that the upper chamber of the wastegate does not remain constantly pressurized. That is exactly how my plumbing works with the PFC using the stock WG solenoid.

If all else fails, hook the solenoid in-line to the side port and control it like an internal wastegate.

And Just for your own reference, here is how a 3 way solenoid works on an internal wastegate. This is exactly what you DON'T want going to the top port of an external wastegate. This is how a Greddy boost controller works when hooked to the stock twins.

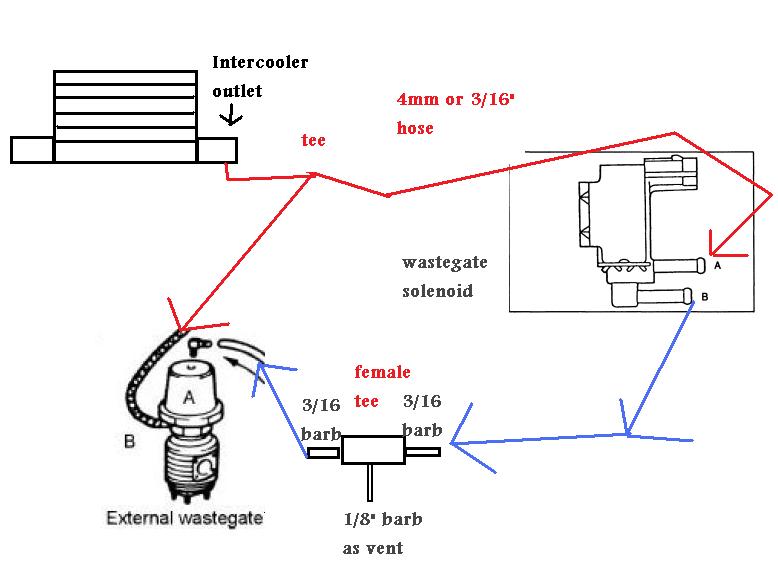

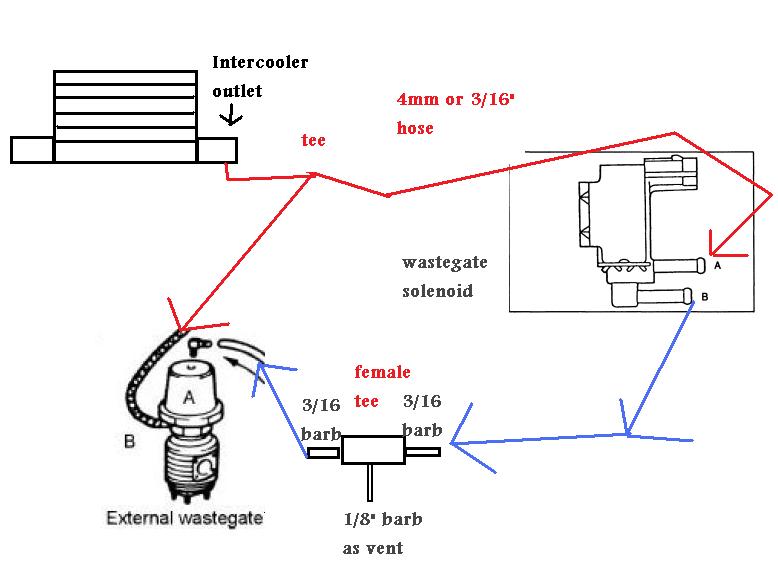

here is how my wastegate is effectively plumbed. it's not unlike your Blitz. It uses a two-way factory wastegate solenoid with a vent.

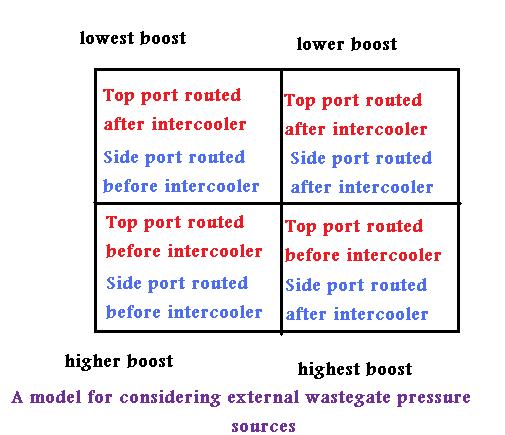

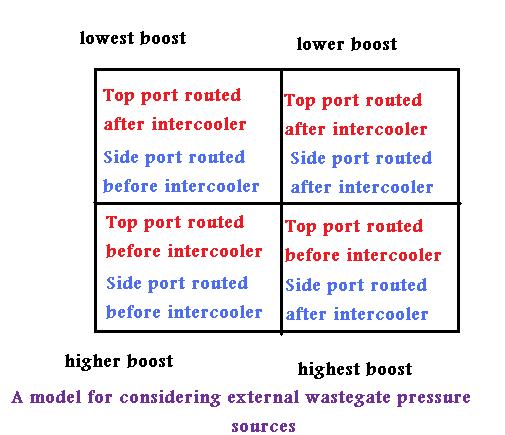

as for whether to hook up before or after the intercooler, consider this decision matrix which assumes all other factors held constant:

When I set the controller to off and I pressurize the system to about 2 psi, the solenoids will open and allow pressure to vent to atmosphere. I would think this should allow for spring pressure to take over but it doesn't work. I have also tested with low boost settings on 1 and it seems to trigger the solenoids at the proper pressure when manually testing the system. Any Ideas.

On an external wastegate with the usual plumbing configuration, the more air that passes through that solenoid the more your boost will increase as it pressurizes the top port of the wastegate. That is why external wastegates use Normally Closed (aka "NC" type) solenoids. When I pressurize the factory NC wastegate solenoid (with it off), I can literally pump it up to 60psi until the hose blows off. No air will pass through at all if the solenoid has not been engaged by the ECU or by me supplying voltage to the solenoid coil. No air should pass to the top port of an external wastegate with the solenoid off!

On an internally wastegated turbo (or on the side port of an external wastegate), the more air that passes through that solenoid the more your boost will DECREASE, with the minimum boost usually being the rated spring pressure. Those use solenoids in the Normally Open (NO) configuration. Air will always pass through them without 12V being applied. Then with 12V is applied, the solenoid will close and the pressure signal will be interrupted. If I'm reading what you are saying correctly, your solenoid behavior is more consistent with an internal wastegate setup.

You need to figure out how to plumb it so that with no voltage applied, no air passes through. When voltage is applied, air passes through, but some is vented out to atmosphere so that the upper chamber of the wastegate does not remain constantly pressurized. That is exactly how my plumbing works with the PFC using the stock WG solenoid.

If all else fails, hook the solenoid in-line to the side port and control it like an internal wastegate.

And Just for your own reference, here is how a 3 way solenoid works on an internal wastegate. This is exactly what you DON'T want going to the top port of an external wastegate. This is how a Greddy boost controller works when hooked to the stock twins.

here is how my wastegate is effectively plumbed. it's not unlike your Blitz. It uses a two-way factory wastegate solenoid with a vent.

as for whether to hook up before or after the intercooler, consider this decision matrix which assumes all other factors held constant:

#7

n/m, i see you said that it's set to wastegate on the back. hmm... I can't see anything wrong with the routing at first glance.

if you remove the solenoid box from the vehicle and pressurize the "IN" port, no air is coming out of the outlet? I would think that none should come out unless voltage is applied. It seems like the blitz operates like a regular two-way solenoid, and when you flip the switch on the back the duty signal is effectively inverted. So with the external wastegate setting, normal duty is 0% and duty increases to pass air to the top port and increase boost. On the internal wastegate setting, normal duty is near 100% (probably 90-95%) so that air would always be flowing to an internal wastegate/side port. And then the duty decreases to reduce the amount of air to the actuator in order to increase boost. The duty values would be normalized in the display so that more duty always = more boost when tuning, regardless of internal or external wastegate configuration. But I've never used a Blitz EBC. Maybe somebody more knowledgeable can chime in.

If you run only pressure to the side port and leave the top port vented, does boost hold at spring pressure?

if you remove the solenoid box from the vehicle and pressurize the "IN" port, no air is coming out of the outlet? I would think that none should come out unless voltage is applied. It seems like the blitz operates like a regular two-way solenoid, and when you flip the switch on the back the duty signal is effectively inverted. So with the external wastegate setting, normal duty is 0% and duty increases to pass air to the top port and increase boost. On the internal wastegate setting, normal duty is near 100% (probably 90-95%) so that air would always be flowing to an internal wastegate/side port. And then the duty decreases to reduce the amount of air to the actuator in order to increase boost. The duty values would be normalized in the display so that more duty always = more boost when tuning, regardless of internal or external wastegate configuration. But I've never used a Blitz EBC. Maybe somebody more knowledgeable can chime in.

If you run only pressure to the side port and leave the top port vented, does boost hold at spring pressure?

Last edited by arghx; 08-17-09 at 11:52 PM. Reason: doube checked the original post

Trending Topics

#8

Where does this bolt go?

Thread Starter

iTrader: (8)

Join Date: Oct 2008

Location: TN

Posts: 315

Likes: 0

Received 0 Likes

on

0 Posts

If I put pressure on the inlet side with no voltage it is closed. In the off position power on the solenoid will vent to atmosphere as soon as it hits any positive pressure at the controller. With the wastegate hooked up with the side port and top vented, it holds perfect boost around 13 to 14 psi. I am tempted to leave it this way, but with my disease (I always want more power) I will soon grow tired of this.

#11

Where does this bolt go?

Thread Starter

iTrader: (8)

Join Date: Oct 2008

Location: TN

Posts: 315

Likes: 0

Received 0 Likes

on

0 Posts

I also tried moving the wg selector switch on the back of the control unit while under boost pressure. I used a pump to simulate boost, and I could hear the solenoid making noises so I figured it was doing what it was supposed to be doing.

Thread

Thread Starter

Forum

Replies

Last Post

Skeese

Adaptronic Engine Mgmt - AUS

65

03-28-17 03:30 PM

stickmantijuana

MoTeC

5

09-10-15 07:58 PM