Why bigger turbos make more HP at the same PSI....

#51

Original Gangster/Rotary!

iTrader: (213)

Originally Posted by CarbonR1

You guys are making it way more complicated than it needs to be. The ideal gas law doesn't apply, and equations aren't going to simplify it at all.

A large turbo at a given boost pressure supplies more mass of air per time than a small turbo at a given boost pressure. That's why they are different, pressure does not tell you how much air you are getting, and neither does volumetric flow (CFM) by itself although they can give you an idea.

Kevin

A large turbo at a given boost pressure supplies more mass of air per time than a small turbo at a given boost pressure. That's why they are different, pressure does not tell you how much air you are getting, and neither does volumetric flow (CFM) by itself although they can give you an idea.

Kevin

. Makes sense to me

. Makes sense to me

#54

Full Member

Join Date: Jun 2004

Location: Houston, TX

Posts: 137

Likes: 0

Received 0 Likes

on

0 Posts

Ergh. I'm sorry, this thread is getting ridiculous. Let's break the problem down into a few easy to understand parts.

1) Flow through the engine - THIS IS THE ONLY MEASURE OF VOLUME THAT MATTERS. PERIOD. Not the CFM of the turbo, nothing else.

Our engine has a chamber size of 0.65 L. This means that at 100% efficiency, the engine will take 0.65L from the intake and output 0.65L into the exhaust. It will take 0.65L of cold 10psi air, 0.65L of hot 100psi air, 0.65L of water, or 0.65L of whatever happens to be in the intake manifold during the intake cycle.

2) Once the intake piping is pressurized, the size of the turbo at the front of it doesn't matter.

Why? Because 650 mL of volume is nothing compared to what is in your intake piping. Let's pretend that we have 10psi in the intake pipe, and we remove the turbo and block of the inlet pipe. That means there is roughly 11L of 10psi held in the intake piping. (8ft of 3in dia. pipe = 11L). So even if the turbo adds zero air, we can pressurize the combustion chamber to 9.6psi (11L / 11.65L * 10psi) with air already in the intake piping. If the turbo is capable of adding 650mL of 10psi air during this time, even this little pressure drop won't happen.

So where does that leave us? We're going to get 650mL of 10psi air into the engine, regardless of turbo size, right?

Wrong.

Here's where it matters:

3) Volumetric efficiency. See that 100% number up on #1? That never happens. Because of air flow issues into and out of the combustion chamber, we can never get a full 650mL of air into the chamber. What restrictions? In this case, the turbo itself is a major restriction in the exhaust path. The more restrictive it is, the less of that used air will get out of the combustion chamber. The twin-turbo exhaust manifold is a twisted complicated and much more restrictive mess than most singles. Let's say the twin can get 80% of the used air out of the combustion chamber during the exhaust phase, and a single can get 90% out. That means the single will have 585mL of space for fresh air on the next intake cycle while the twin will have only 520. That's an 65 extra mL of air to burn. That matters.

So, efficiency matters. A single will allow more fresh air into your combustion chamber because of less exhaust restriction.

Is that the only gain? No, but lets look at what we have first:

A restrictive exhaust path means 520mL of 10psi air into the combustion chamber each cycle.

A less restrictive exhaust path means 585mL of 10psi air.

4) So some people have mentioned PV=nRT. Is this relevant? Absolutely, and the relevant term here is that "n". That's the number of (mols of) air molecules getting into the combustion chamber.

So we've got P, it's 10psi.

We've got V, either 520 or 585.

R is a constant (8.314 472 m^3*Pa / K*mol)

n is the number we're looking for.

That leaves T, temperature (in Kelvin)

n = P*V / R*T

That means if one turbo is putting air out at 80F (300Kelvin) and one is putting air out at 100F (311K), the cooler one is getting 3.6% more air molecules into the same space as the hotter one.

So, let's put it all together. If the single is both more efficient WRT an exhaust path and also puts out cooler air, it can put in (Vs/Ts) molecules vs. (Vt/Tt) molecules on the single (s=single t=twin). So (585/300) / (520/311) = 16.6% more air molecules into the engine at the EXACT SAME PSI!

NOTE: The only things we looked at were INTAKE TEMPERATURE and EXHAUST RESTRICTION. CFM of the turbo DOES NOT MATTER. If you have two single turbo setups that restrict exhaust about the same and don't heat the air all that much, you will get IDENTICAL POWER AT THE SAME PSI. PERIOD. It doesn't matter if one can flow 10 gazillion CFM more than the other.

MYTH DISPELLED:

Why PULSING does not matter:

See #2. As long as the turbo can add 650mL of pressurized air during the amount of time between successive intakes, pulsing is irrelevant. If the average PSI (i.e. what you see on your boost gauge) is 10 psi, a minimum of 9.6 is getting into the engine on each cycle. FWIW, because our twins cannot always do this, our intake pressure starts to drop at higher rpms.

1) Flow through the engine - THIS IS THE ONLY MEASURE OF VOLUME THAT MATTERS. PERIOD. Not the CFM of the turbo, nothing else.

Our engine has a chamber size of 0.65 L. This means that at 100% efficiency, the engine will take 0.65L from the intake and output 0.65L into the exhaust. It will take 0.65L of cold 10psi air, 0.65L of hot 100psi air, 0.65L of water, or 0.65L of whatever happens to be in the intake manifold during the intake cycle.

2) Once the intake piping is pressurized, the size of the turbo at the front of it doesn't matter.

Why? Because 650 mL of volume is nothing compared to what is in your intake piping. Let's pretend that we have 10psi in the intake pipe, and we remove the turbo and block of the inlet pipe. That means there is roughly 11L of 10psi held in the intake piping. (8ft of 3in dia. pipe = 11L). So even if the turbo adds zero air, we can pressurize the combustion chamber to 9.6psi (11L / 11.65L * 10psi) with air already in the intake piping. If the turbo is capable of adding 650mL of 10psi air during this time, even this little pressure drop won't happen.

So where does that leave us? We're going to get 650mL of 10psi air into the engine, regardless of turbo size, right?

Wrong.

Here's where it matters:

3) Volumetric efficiency. See that 100% number up on #1? That never happens. Because of air flow issues into and out of the combustion chamber, we can never get a full 650mL of air into the chamber. What restrictions? In this case, the turbo itself is a major restriction in the exhaust path. The more restrictive it is, the less of that used air will get out of the combustion chamber. The twin-turbo exhaust manifold is a twisted complicated and much more restrictive mess than most singles. Let's say the twin can get 80% of the used air out of the combustion chamber during the exhaust phase, and a single can get 90% out. That means the single will have 585mL of space for fresh air on the next intake cycle while the twin will have only 520. That's an 65 extra mL of air to burn. That matters.

So, efficiency matters. A single will allow more fresh air into your combustion chamber because of less exhaust restriction.

Is that the only gain? No, but lets look at what we have first:

A restrictive exhaust path means 520mL of 10psi air into the combustion chamber each cycle.

A less restrictive exhaust path means 585mL of 10psi air.

4) So some people have mentioned PV=nRT. Is this relevant? Absolutely, and the relevant term here is that "n". That's the number of (mols of) air molecules getting into the combustion chamber.

So we've got P, it's 10psi.

We've got V, either 520 or 585.

R is a constant (8.314 472 m^3*Pa / K*mol)

n is the number we're looking for.

That leaves T, temperature (in Kelvin)

n = P*V / R*T

That means if one turbo is putting air out at 80F (300Kelvin) and one is putting air out at 100F (311K), the cooler one is getting 3.6% more air molecules into the same space as the hotter one.

So, let's put it all together. If the single is both more efficient WRT an exhaust path and also puts out cooler air, it can put in (Vs/Ts) molecules vs. (Vt/Tt) molecules on the single (s=single t=twin). So (585/300) / (520/311) = 16.6% more air molecules into the engine at the EXACT SAME PSI!

NOTE: The only things we looked at were INTAKE TEMPERATURE and EXHAUST RESTRICTION. CFM of the turbo DOES NOT MATTER. If you have two single turbo setups that restrict exhaust about the same and don't heat the air all that much, you will get IDENTICAL POWER AT THE SAME PSI. PERIOD. It doesn't matter if one can flow 10 gazillion CFM more than the other.

MYTH DISPELLED:

Why PULSING does not matter:

See #2. As long as the turbo can add 650mL of pressurized air during the amount of time between successive intakes, pulsing is irrelevant. If the average PSI (i.e. what you see on your boost gauge) is 10 psi, a minimum of 9.6 is getting into the engine on each cycle. FWIW, because our twins cannot always do this, our intake pressure starts to drop at higher rpms.

#55

Thankyou kashent, that has helped me alot.

I was not understanding the concept at all for the first 3.9 pages of this thread! I always knew bigger turbos produced more power, but wasnt entirely sure why - i was of the school of thought that the intake always has the same level of restriction, and thus will only allow through the same amount of air given the same amount of pressure (in the way that if you excert 10 lbs of pressure on the end a full syringe for 1 second, say 10ml of fluid goes through. To get more through you HAVE to press harder)

I did not think about the fact that there are dual restrictions (back pressure during overlap, not only restricted by intake) and did not think about the temprature of the intake charge.

So basically, big turbos make more power because:

There is less pressure in the combustion chamber at time of intake port opening because the more effecient exhaust setup and larger exducer (is that the right term?) on the hot side of a single gets rid of the pressure from the previous combustion cycle quicker, so more room to force in fresh air.

As a turbo moves up its efficiency range, the air it outputs starts to get hotter. A set of twins at 14psi are nearing the top of their efficency range, and as such the air being expelled is hotter and thus less dense compared to a single at the same psi. So 1 cubic foot of 80c air at 10psi contains maybe (hypothetically of course) 100 oxygen molecules, but 1 cubic foot of 40c air at 10psi contains 200 oxygen moleculs

Is my thinking correct?

Also, i KNOW there will be alot more than 200 oxygen moleculs in a cf of air before anyone points it out

I was not understanding the concept at all for the first 3.9 pages of this thread! I always knew bigger turbos produced more power, but wasnt entirely sure why - i was of the school of thought that the intake always has the same level of restriction, and thus will only allow through the same amount of air given the same amount of pressure (in the way that if you excert 10 lbs of pressure on the end a full syringe for 1 second, say 10ml of fluid goes through. To get more through you HAVE to press harder)

I did not think about the fact that there are dual restrictions (back pressure during overlap, not only restricted by intake) and did not think about the temprature of the intake charge.

So basically, big turbos make more power because:

There is less pressure in the combustion chamber at time of intake port opening because the more effecient exhaust setup and larger exducer (is that the right term?) on the hot side of a single gets rid of the pressure from the previous combustion cycle quicker, so more room to force in fresh air.

As a turbo moves up its efficiency range, the air it outputs starts to get hotter. A set of twins at 14psi are nearing the top of their efficency range, and as such the air being expelled is hotter and thus less dense compared to a single at the same psi. So 1 cubic foot of 80c air at 10psi contains maybe (hypothetically of course) 100 oxygen molecules, but 1 cubic foot of 40c air at 10psi contains 200 oxygen moleculs

Is my thinking correct?

Also, i KNOW there will be alot more than 200 oxygen moleculs in a cf of air before anyone points it out

#56

Where do I even begin... Trying to talk ourself out of an untenable corner are we?

Trying to talk ourself out of an untenable corner are we?

If you define spooling as rotation then the turbo is always spooling; however, if you define spooling at getting up to speed so that the turbo can produce the desired boost (which is what it really refers to), then sorry my friend. The point is that a larger turbo cannot rotate at the same RPM as a smaller turbo and make the same boost. Once you switch up the RPMs you're whole surface area explanation goes kaput. CFM is the measure of how many cubic feet of air can be moved per minute. at the same RPM a larger compressor will move Imore CFM?

Idon't understand where you are missing this....

CFM takes RPMs and Compressor blades. Volume alone does not suffice as an explanation man. sorry.

OK, a smaller turbo can achieve the same PSI at different COMPRESSOR WHEEL RPM read NOT engine RPM! lol. I think we're talking about 2 different subjects.

SEE ABOVE

[QUOTE]If two differently sized turbos were rotating at the same speed, while the LARGER turbo would compress more AIR (ie volume), BECAUSE of it's greater volume (and that area is in the denominator in the pressure equation), the psi it would be running at would be LOWER. Ie, the SMALLER turbo would indeed be compressing a SMALLER volume of air, yet it's PRESSURE (psi) would be HIGHER. And that's the fundamental point I'm trying to get ya to see. PSI is NOT NOT NOT directly related to turbo area; in fact it's *inversely* related.[QUOTE]Think about what you just said.... (think intake volume - which is the same for every turbo).

These are the parts we should be getting into because they are the backbone of a good turbo upgrade.

Originally Posted by FDNewbie

That's where you're incorrect. Reason being is you're speaking in abstract talk. Once the turbo is spooling it IS making boost. So "sufficient boost" is completely relative based upon what you're comparing or trying to achieve.

For example, the stock twins are considered spooling until 10psi, right? And at 10 psi they make 255hp, correct? If you stuck a GT40 on a 3rd gen for example (which is capable of much higher boost than the stocker), and saw the power output at 10psi, you'd see it'll make MORE than the stockers' 255hp, despite it still being IN SPOOL. Why? Because your reference point (when you're out of spool) has changed.

In simple terms, just b/c a turbo is in spool does NOT mean it isn't creating enough power. A spooling turbo produces boost, and ANY level of boost creates power. No nothing's null and void here

For example, the stock twins are considered spooling until 10psi, right? And at 10 psi they make 255hp, correct? If you stuck a GT40 on a 3rd gen for example (which is capable of much higher boost than the stocker), and saw the power output at 10psi, you'd see it'll make MORE than the stockers' 255hp, despite it still being IN SPOOL. Why? Because your reference point (when you're out of spool) has changed.

In simple terms, just b/c a turbo is in spool does NOT mean it isn't creating enough power. A spooling turbo produces boost, and ANY level of boost creates power. No nothing's null and void here

If you define spooling as rotation then the turbo is always spooling; however, if you define spooling at getting up to speed so that the turbo can produce the desired boost (which is what it really refers to), then sorry my friend. The point is that a larger turbo cannot rotate at the same RPM as a smaller turbo and make the same boost. Once you switch up the RPMs you're whole surface area explanation goes kaput. CFM is the measure of how many cubic feet of air can be moved per minute. at the same RPM a larger compressor will move Imore CFM?

Idon't understand where you are missing this....

Again, that's where you're missing the point. At the same psi (which is what you've been comparing all along), a smaller turbo will be FULLY spooled while a large turbo will STILL be spooling. BOTH will be creating boost, BOTH will net in greater power. Yet despite the pressure rating being the same, the larger turbo will make MORE power at that same psi, despite it being in spool, simply b/c that VOLUME of air being compressed to reach that psi is LARGER than the volume of air being compressed by the smaller turbo.

Not accepting it

Theoretically, sure. But NOT at the same PSI!!! Which is what your original question was after, was it not?

Theoretically, sure. But NOT at the same PSI!!! Which is what your original question was after, was it not?

Sure it does, but not in the way you're thinking. Engine speed (rpm) determines how much exhaust gas is coming out. Spool is nothing more than the engine speed (rpm) needed to create enough exhaust gas flow to spool the turbo. .....

[QUOTE]If two differently sized turbos were rotating at the same speed, while the LARGER turbo would compress more AIR (ie volume), BECAUSE of it's greater volume (and that area is in the denominator in the pressure equation), the psi it would be running at would be LOWER. Ie, the SMALLER turbo would indeed be compressing a SMALLER volume of air, yet it's PRESSURE (psi) would be HIGHER. And that's the fundamental point I'm trying to get ya to see. PSI is NOT NOT NOT directly related to turbo area; in fact it's *inversely* related.[QUOTE]Think about what you just said.... (think intake volume - which is the same for every turbo).

The very last part I agree w/. The first about charge velocity and backpressure...I'm not even getting into those. That's involving WAYY too many variables. Agree and bang out the core details before expanding and including compounding factors and variables. It'll make life much easier Rob

~Ramy

~Ramy

#57

1) Flow through the engine - THIS IS THE ONLY MEASURE OF VOLUME THAT MATTERS. PERIOD. Not the CFM of the turbo, nothing else.

2) Once the intake piping is pressurized, the size of the turbo at the front of it doesn't matter..... At all?

2) Once the intake piping is pressurized, the size of the turbo at the front of it doesn't matter..... At all?

Why? Because 650 mL of volume is nothing compared to what is in your intake piping.

Let's pretend that we have 10psi in the intake pipe, and we remove the turbo and block of the inlet pipe. That means there is roughly 11L of 10psi held in the intake piping. (8ft of 3in dia. pipe = 11L). So even if the turbo adds zero air, we can pressurize the combustion chamber to 9.6psi (11L / 11.65L * 10psi) with air already in the intake piping. If the turbo is capable of adding 650mL of 10psi air during this time, even this little pressure drop won't happen.

The combustion chamber is not at atmospheric pressure, it is a vacuum and as such the intake charge will depressurize once the intake ports open. If the turbo can repressurize the charge quickly you will get more air into the intake. I don't see how this can be ignored....

So where does that leave us? We're going to get 650mL of 10psi air into the engine, regardless of turbo size, right?

Wrong.

Here's where it matters:

3) Volumetric efficiency. See that 100% number up on #1? That never happens. Because of air flow issues into and out of the combustion chamber, we can never get a full 650mL of air into the chamber. What restrictions? In this case, the turbo itself is a major restriction in the exhaust path. The more restrictive it is, the less of that used air will get out of the combustion chamber. The twin-turbo exhaust manifold is a twisted complicated and much more restrictive mess than most singles. Let's say the twin can get 80% of the used air out of the combustion chamber during the exhaust phase, and a single can get 90% out. That means the single will have 585mL of space for fresh air on the next intake cycle while the twin will have only 520. That's an 65 extra mL of air to burn. That matters.

Wrong.

Here's where it matters:

3) Volumetric efficiency. See that 100% number up on #1? That never happens. Because of air flow issues into and out of the combustion chamber, we can never get a full 650mL of air into the chamber. What restrictions? In this case, the turbo itself is a major restriction in the exhaust path. The more restrictive it is, the less of that used air will get out of the combustion chamber. The twin-turbo exhaust manifold is a twisted complicated and much more restrictive mess than most singles. Let's say the twin can get 80% of the used air out of the combustion chamber during the exhaust phase, and a single can get 90% out. That means the single will have 585mL of space for fresh air on the next intake cycle while the twin will have only 520. That's an 65 extra mL of air to burn. That matters.

So, let's put it all together. If the single is both more efficient WRT an exhaust path and also puts out cooler air, it can put in (Vs/Ts) molecules vs. (Vt/Tt) molecules on the single (s=single t=twin). So (585/300) / (520/311) = 16.6% more air molecules into the engine at the EXACT SAME PSI!

NOTE: The only things we looked at were INTAKE TEMPERATURE and EXHAUST RESTRICTION. CFM of the turbo DOES NOT MATTER. If you have two single turbo setups that restrict exhaust about the same and don't heat the air all that much, you will get IDENTICAL POWER AT THE SAME PSI. PERIOD. It doesn't matter if one can flow 10 gazillion CFM more than the other.

MYTH DISPELLED:

Why PULSING does not matter:

See #2. As long as the turbo can add 650mL of pressurized air during the amount of time between successive intakes, pulsing is irrelevant. If the average PSI (i.e. what you see on your boost gauge) is 10 psi, a minimum of 9.6 is getting into the engine on each cycle. FWIW, because our twins cannot always do this, our intake pressure starts to drop at higher rpms.

NOTE: The only things we looked at were INTAKE TEMPERATURE and EXHAUST RESTRICTION. CFM of the turbo DOES NOT MATTER. If you have two single turbo setups that restrict exhaust about the same and don't heat the air all that much, you will get IDENTICAL POWER AT THE SAME PSI. PERIOD. It doesn't matter if one can flow 10 gazillion CFM more than the other.

MYTH DISPELLED:

Why PULSING does not matter:

See #2. As long as the turbo can add 650mL of pressurized air during the amount of time between successive intakes, pulsing is irrelevant. If the average PSI (i.e. what you see on your boost gauge) is 10 psi, a minimum of 9.6 is getting into the engine on each cycle. FWIW, because our twins cannot always do this, our intake pressure starts to drop at higher rpms.

Last edited by wanklin; 04-25-07 at 06:13 AM.

#59

On flats

iTrader: (29)

Join Date: Oct 2004

Location: Albuquerque

Posts: 1,379

Likes: 0

Received 0 Likes

on

0 Posts

My physics 1 book has some intro thermodynamics in it, and it breezes over it. . .that's neither here nor there.

My previous discussion was an oversimplification, as I said at the end in my disclaimer. I don't see why the Ideal Gas Law doesn't apply. . .

To be perfectly clear, the system that I was considering was everything AFTER the compressor housing outlet. I was treating the turbos as "black boxes" and forcing conclusions about the nature of the resulting intake charge to be drawn that would explain what about said charge MUST be different to accomodate the forced conclusions. This necessarily speaks to the nature of the operation of the turbo, which is that in real basic terms, bigger turbos compress the same amount of air as littler turbos with much less effort (work = heat). I agree that the ideal gas law is a VERY poor description of fluid dynamics INSIDE the compressor housing.

Since we are talking about a compressed gas, the Van der Waals equation should be applied since the assumption that the volume the gas occupies is largely void isn't valid any longer. All that Van der Waals correction does is add constants and exponents that end up dividing out of both sides of the equality anyway, so to keep it simple, I didn't include them. Damn we need an equation editor on this forum.

At any rate, I still maintain that put very simply:

in real basic terms, bigger turbos compress the same amount of air as littler turbos with much less effort (work = heat; heat = less dense air = less oxygen to feed combustion = less power)

I'm glad that no one is contending that PSI is all that matters, I've had those discussions, and boy those people are hard to talk to.

Good perspectives on the issue all around generally.

ryan

My previous discussion was an oversimplification, as I said at the end in my disclaimer. I don't see why the Ideal Gas Law doesn't apply. . .

To be perfectly clear, the system that I was considering was everything AFTER the compressor housing outlet. I was treating the turbos as "black boxes" and forcing conclusions about the nature of the resulting intake charge to be drawn that would explain what about said charge MUST be different to accomodate the forced conclusions. This necessarily speaks to the nature of the operation of the turbo, which is that in real basic terms, bigger turbos compress the same amount of air as littler turbos with much less effort (work = heat). I agree that the ideal gas law is a VERY poor description of fluid dynamics INSIDE the compressor housing.

Since we are talking about a compressed gas, the Van der Waals equation should be applied since the assumption that the volume the gas occupies is largely void isn't valid any longer. All that Van der Waals correction does is add constants and exponents that end up dividing out of both sides of the equality anyway, so to keep it simple, I didn't include them. Damn we need an equation editor on this forum.

At any rate, I still maintain that put very simply:

in real basic terms, bigger turbos compress the same amount of air as littler turbos with much less effort (work = heat; heat = less dense air = less oxygen to feed combustion = less power)

I'm glad that no one is contending that PSI is all that matters, I've had those discussions, and boy those people are hard to talk to.

Good perspectives on the issue all around generally.

ryan

#60

development

Originally Posted by NissanConvert

However, if the rest of the system does not allow for the increase in flow how does it?

#61

Originally Posted by wanklin

The engine isn't really seeing 10PSI, it's seeing whatever the turbo can get into the intake ports before they close. That's why flow matters. A large turbo will move more air in that short window of time. If the engine was getting 10PSI boost internally with both setups flow wouldn't mean squat. Flow means nothing once the ports are sealed.

aren't we saying the same thing?

aren't we saying the same thing?

#62

2/4 wheel cornering fiend

Originally Posted by kashent

So, efficiency matters. A single will allow more fresh air into your combustion chamber because of less exhaust restriction.

...if one turbo is putting air out at 80F (300Kelvin) and one is putting air out at 100F (311K), the cooler one is getting 3.6% more air molecules into the same space as the hotter one.

...if one turbo is putting air out at 80F (300Kelvin) and one is putting air out at 100F (311K), the cooler one is getting 3.6% more air molecules into the same space as the hotter one.

#63

In response to Montego:

Kinda, but not really because you don't take CFM into account. IOW you just established that the large turbo is doing less work than the small guy, but you say nothing about flow or what happens inside the engine. Not saying you are wrong, just that they are two different statements.

Kinda, but not really because you don't take CFM into account. IOW you just established that the large turbo is doing less work than the small guy, but you say nothing about flow or what happens inside the engine. Not saying you are wrong, just that they are two different statements.

#64

Originally Posted by wanklin

In response to Montego:

Kinda, but not really because you don't take CFM into account. IOW you just established that the large turbo is doing less work than the small guy, but you say nothing about flow or what happens inside the engine. Not saying you are wrong, just that they are two different statements.

Kinda, but not really because you don't take CFM into account. IOW you just established that the large turbo is doing less work than the small guy, but you say nothing about flow or what happens inside the engine. Not saying you are wrong, just that they are two different statements.

....

....

Originally Posted by montego

blah.. blah..

Single turbo:

Pressure at the manifold = 10 psi

Twins:

Pressure at the manifold = 10 psi

CFM of single > than CFM of twins

Using a single, the end result is alot more oxygen molecules at the COMBUSTION chamber due to a higher CFM. In the combustion chamber: Pressure using a single does not = the same pressure as using the twins.

its are all about CFM. PV=NRT directly applied at the manifold, where the pressure is measured, does NOT depent on how much air is moving through it.

Single turbo:

Pressure at the manifold = 10 psi

Twins:

Pressure at the manifold = 10 psi

CFM of single > than CFM of twins

Using a single, the end result is alot more oxygen molecules at the COMBUSTION chamber due to a higher CFM. In the combustion chamber: Pressure using a single does not = the same pressure as using the twins.

its are all about CFM. PV=NRT directly applied at the manifold, where the pressure is measured, does NOT depent on how much air is moving through it.

oh well...

Last edited by Montego; 04-25-07 at 12:01 PM.

#65

The actual flow equation from Garret: http://www.turbobygarrett.com/turbob...o_tech103.html

Where:

∑ Wa = Airflowactual (lb/min)

∑ MAP = Manifold Absolute Pressure (psia) =35.1 psia

∑ R = Gas Constant = 639.6

∑ Tm = Intake Manifold Temperature (degrees F) =130

∑ VE = Volumetric Efficiency = 0.98

∑ N = Engine speed (RPM) = 5000rpm

∑ Vd = engine displacement (Cubic Inches, convert from liters to CI by multiplying by 61, ex. 2.0 liters * 61 = 122 CI)

example:

Where:

∑ Wa = Airflowactual (lb/min)

∑ MAP = Manifold Absolute Pressure (psia) =35.1 psia

∑ R = Gas Constant = 639.6

∑ Tm = Intake Manifold Temperature (degrees F) =130

∑ VE = Volumetric Efficiency = 0.98

∑ N = Engine speed (RPM) = 5000rpm

∑ Vd = engine displacement (Cubic Inches, convert from liters to CI by multiplying by 61, ex. 2.0 liters * 61 = 122 CI)

example:

#66

Racecar - Formula 2000

I have not read all the posts on this, so this may be repetitive...

Two thoughts about how a larger turbo (or turbos) can result in more HP at the same boost level:

1. A larger turbo will have more flow area, so exhaust can exit with less backpressure at the exhaust port. Even at the same boost level, the lower backpressure at the exhaust port will raise HP.

2. A larger turbo will likely be more efficient at high flow/HP, generating less heat in the compressed air at the same boost level, resulting (even with an intercooler) in a denser intake charge, and raising HP. This increase in efficiency would further reduce backpressure.

Dave

Two thoughts about how a larger turbo (or turbos) can result in more HP at the same boost level:

1. A larger turbo will have more flow area, so exhaust can exit with less backpressure at the exhaust port. Even at the same boost level, the lower backpressure at the exhaust port will raise HP.

2. A larger turbo will likely be more efficient at high flow/HP, generating less heat in the compressed air at the same boost level, resulting (even with an intercooler) in a denser intake charge, and raising HP. This increase in efficiency would further reduce backpressure.

Dave

#67

Corky Bell - Maximum Boost (read more HERE)

- When operating at maximum load, the large compressor puts less heat into the intake charge.

- The large turbine creates less exhaust manifold back pressure, further reducing the heat load.

- The design staff wanted a powerful automobile.

The airflow rate through an engine is usually referred to as cubic feet per minute (cfm) of air at standard atmospheric pressure. The technically correct but less-used term is pounds of air per minute. This book will use the semi-incorrect term "cfm."

To calculate the airflow rate of an engine without a turbo--i.e. no boost:

Here, flow rate is in cfm and displacement is in cubic inches. The .5 is due to the fact that a four-stroke-cycle engine fills its cylinders only on one-half the revolutions. Ev is volumetric efficiency. The 1728 converts cubic inches to cubic feet. Example: In a small-block Ford, let size = 302 cid, rpm = 5500, and Ev= 85%. Then

Fig. 3-5. The volume rate of flow (cfm) for four-stroke-cycle engines. Choose an engine size (the x-axis) and an rpm, and the cfm is shown on the y-axis.

Fig. 3-5. The volume rate of flow (cfm) for four-stroke-cycle engines. Choose an engine size (the x-axis) and an rpm, and the cfm is shown on the y-axis. Chapter 3, page 27

With the basic engine flow rate established, the flow rate under boost can be determined. The pressure ratio times the basic engine flow rate then becomes the approximate flow rate under boost (neglecting volumetric efficiency): the number weíre really after. In the small-block Ford operating at 12 psi boost:

To convert cfm to the more correct term of pounds of air per minute, cfm must be multiplied by the density of air at the working altitude (see table 3-1). Compressor efficiency.

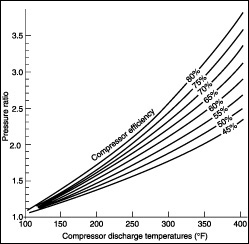

In concept, compressor efficiency is a measure of how well the compressor wheel can pump air without heating the air more than thermodynamic law says it should. Thermodynamics says the air temperature should rise a certain amount based on the pressure ratio. That temperature rise would be called the ideal temperature rise. When the temperature is actually measured, it is always higher than the thermodynamic calculation indicates it should be. The measured temperature rise is, of course, the real temperature rise. The efficiency is the calculated temperature rise divided by the real temperature rise. In essence, efficiency is how well the compressor really behaves with respect to how well thermodynamics says it should behave. All compressor wheels operate with peak percentage efficiencies in the seventies. Choosing compressor size becomes mostly a question of where that compressorís efficiency peaks with respect to the flow capabilities of the engine/turbo system. With an understanding of the terms pressure ratio, density ratio, airflow rate, and compressor efficiency, the basic information necessary to select a compressor for a given application is at hand. In general, under 7 psi is low boost, 7-12 psi is medium boost, and over 12 psi is high boost. Working through the example of the small-block Ford with several choices of compressors will illustrate the process of calculation as well as the importance of placement of the efficiency peak. A study of Fig. 3-6 indicates the effect of a compressorís efficiency on charge temperatures. In general, compressor effi-

Table 3-1. Variation of air pressure and temperature with altitude.

Table 3-1. Variation of air pressure and temperature with altitude. Chapter 3, page 28

Fig. 3-6. Compressor discharge temperature versus pressure ratio. Why one wants to secure the highest compressor efficiency possible: the greater the efficiency, the lower the temperature.

Fig. 3-6. Compressor discharge temperature versus pressure ratio. Why one wants to secure the highest compressor efficiency possible: the greater the efficiency, the lower the temperature. Chapter 3, page 29

ciency without an intercooler should be at least 60%. If the system includes an intercooler, minimum efficiency can be somewhat less (see Chapter 5).

#68

Using the equation above from Garret (and supported by Corky Bell).

Actual Flow = Map (ambient+boost) x Volumetric efficiency x RPM/2 x displacement

all divided by gas flow and intake temps.

Our scenario: 10lbs boost on large and small turbo assuming intake temps are the same for both. Yes this is possible if the larger turbo was not intercooled. Just bare with me..lol Also assume that both setups have the same amount of exhaust backpressure (ignore reality for a second will ya ;o)...)

.....................small turbo.......... large turbo

Boost.................10PSI................10PSI

flow....................less...................more

RPM...................fixed.................fixed

Displ..................fixed..................fixe d

intake temp........fixed..................fixed

exhst bck press...fixed..................fixed

gas constant.......fixed..................fixed

VE......................less...................more

Conclusion: If intake temps, backpressure, boost and RPM are held constant for both setups the larger turbo will make more power because volumetric efficiency has increased due to the greater flow of the larger compressor wheel at 10PSI.

DECREASED INTAKE TEMPS and BACKPRESSURE ARE NOT THE ONLY REASONS FOR PERFORMANCE GAIN.

But the above conclusion is ofcourse incomplete in the real world as larger turbos do decrease backpressure (further stimulating volumetric efficiency)

and

A larger turbo running within it 73% efficiency island or there abouts will produce a more dense intake charge assuming that the same intercooler is used for both setups.

The end result of a larger turbo operating in it's efficiency range is more power, but it comes from increased flow, as well as reduced exhaust backpressure and lower intake temps.

Last edited by wanklin; 04-25-07 at 01:17 PM.

#69

Racecar - Formula 2000

But, everything else being equal, increased flow results from increased efficiency, lower intake temps, and less backpressure.

Dave

#70

Yes, but you are thinking too black&white my friend. These properties are synergetic, IOW they all feed off of each other. You can hook the compressors up to electric spinners and observe that the larger turbines still move more air at a given level of boost ;o) = increased VE.

#71

Racecar - Formula 2000

Originally Posted by wanklin

Yes, but you are thinking too black&white my friend. These properties are synergetic, IOW they all feed off of each other. You can hook the compressors up to electric spinners and observe that the larger turbines still move more air at a given level of boost ;o) = increased VE.

In the real world, at a given engine RPM, the ONLY way more air (resulting in more HP) can flow through the entire system (turbos, engine, exhaust) without raising boost pressure or improving porting is by increasing intake air density and lowering exhaust backpressure.

Think about it.

Dave

Last edited by DaveW; 04-25-07 at 01:33 PM.

#72

Please somebody help!!!

iTrader: (1)

Join Date: Sep 2005

Location: Woodridge, IL

Posts: 1,442

Likes: 0

Received 0 Likes

on

0 Posts

Okay- my hang up the "everything remaining the same" has become clear. Because not only the manifold changes (increasing flow) but the turbine side also changes (increasing flow) so the all things staying the same (in abstract) would be:

Putting t04r compressors on the stock twins turbines (& manifold) @ 10psi is going to make nearly identical HP at a given RPM.

Conversely putting a stock twin compressor on a t04r turbine (& manifold) could make more power (in theory) than the stock twins because of the reduction in back pressure from the new manifold and turbine.

Apples to oranges- suddenly the fog drifted away and everything became clear.

Putting t04r compressors on the stock twins turbines (& manifold) @ 10psi is going to make nearly identical HP at a given RPM.

Conversely putting a stock twin compressor on a t04r turbine (& manifold) could make more power (in theory) than the stock twins because of the reduction in back pressure from the new manifold and turbine.

Apples to oranges- suddenly the fog drifted away and everything became clear.

#73

Originally Posted by DaveW

In this case you are moving air without the limitations of the engine's displacement.

In the real world, at a given engine RPM, the ONLY way more air (resulting in more HP) can flow through the entire system (turbos, engine, exhaust) without raising boost pressure or improving porting is by increasing intake air density and lowering exhaust backpressure.

Think about it.

Dave

In the real world, at a given engine RPM, the ONLY way more air (resulting in more HP) can flow through the entire system (turbos, engine, exhaust) without raising boost pressure or improving porting is by increasing intake air density and lowering exhaust backpressure.

Think about it.

Dave

#74

Racecar - Formula 2000

OK. I read it. How does anything there contradict what I said above?

BTW, nothing I said contradicts the possibility that larger more efficient turbos could produce more HP at the same boost level (measured at the intake port).

Dave

BTW, nothing I said contradicts the possibility that larger more efficient turbos could produce more HP at the same boost level (measured at the intake port).

Dave

Last edited by DaveW; 04-25-07 at 01:49 PM.

#75

Originally Posted by NissanConvert

Okay- my hang up the "everything remaining the same" has become clear. Because not only the manifold changes (increasing flow) but the turbine side also changes (increasing flow) so the all things staying the same (in abstract) would be:

Putting t04r compressors on the stock twins turbines (& manifold) @ 10psi is going to make nearly identical HP at a given RPM.

Putting t04r compressors on the stock twins turbines (& manifold) @ 10psi is going to make nearly identical HP at a given RPM.

Conversely putting a stock twin compressor on a t04r turbine (& manifold) could make more power (in theory) than the stock twins because of the reduction in back pressure from the new manifold and turbine.

Apples to oranges- suddenly the fog drifted away and everything became clear.

Apples to oranges- suddenly the fog drifted away and everything became clear.