Headlight retract issue - bad wiring? Searched and researched, need help!

#1

I love RX-7s

Thread Starter

iTrader: (1)

Join Date: Jul 2007

Location: Sydney

Posts: 238

Likes: 0

Received 0 Likes

on

0 Posts

Headlight retract issue - bad wiring? Searched and researched, need help!

G'day,

Please read whole post, I've already tried the obvious with this one.

Several months ago the headlights on my '82 would only go down 1 minute to 30 minutes after I'd left the car. Sometimes they would go down straight away, other times it'd take ages, but eventually they went down. After a while they stopped retracting altogether, and I've been hand-winding for ages now. Only with the holidays have I had enough time to pursue it.

I've tried all the obvious things - fusible links, fuses, retract button in the console, etc. Its not the motors or anything mechanical because it happens to both headlights.

I have troubleshooted the wiring and it doesn't look good. I've attached a wiring diagram with annotations showing what works and what doesn't. The green paths are what I've tested for continuity successfully. The orange path (inside the combination switch) is a bad connection - sometimes I get continuity if I play with the stalk, other times I don't. The red path is where I'm pretty certain the problem is.

So to explain the red path... I put one electrode of the multimeter on the female connector of X-02 RY (red, yellow stripe) under the dash, and the other electrode on the female connector of E-04 RY (red, yellow stripe) next to the drivers-right retractor in the engine bay. There is no continuity between these two points. The reason the red stops at the junction is because I have also tested between E-04 RY and E-03 RY (connector for drivers-left retractor) and there is continuity.

The blue represents where I jumped the connection and was able to get the headlight to retract.

So, where to now? Has anyone encountered this before?

My theory is that the bad connection in the combination switch (the original cause of the intermittent retracting), caused the wiring to short out somewhere on the red path. But that seems so unlikely! How can wiring just short out? Wouldn't a fuse blow? (Again, I've tested all fuses)

Please help RX-7 wizards!

Diagram taken from 1982 wiring diagram, which can be found here: http://www.wankel.net/~krwright/cars/rx7/manuals.html

Please read whole post, I've already tried the obvious with this one.

Several months ago the headlights on my '82 would only go down 1 minute to 30 minutes after I'd left the car. Sometimes they would go down straight away, other times it'd take ages, but eventually they went down. After a while they stopped retracting altogether, and I've been hand-winding for ages now. Only with the holidays have I had enough time to pursue it.

I've tried all the obvious things - fusible links, fuses, retract button in the console, etc. Its not the motors or anything mechanical because it happens to both headlights.

I have troubleshooted the wiring and it doesn't look good. I've attached a wiring diagram with annotations showing what works and what doesn't. The green paths are what I've tested for continuity successfully. The orange path (inside the combination switch) is a bad connection - sometimes I get continuity if I play with the stalk, other times I don't. The red path is where I'm pretty certain the problem is.

So to explain the red path... I put one electrode of the multimeter on the female connector of X-02 RY (red, yellow stripe) under the dash, and the other electrode on the female connector of E-04 RY (red, yellow stripe) next to the drivers-right retractor in the engine bay. There is no continuity between these two points. The reason the red stops at the junction is because I have also tested between E-04 RY and E-03 RY (connector for drivers-left retractor) and there is continuity.

The blue represents where I jumped the connection and was able to get the headlight to retract.

So, where to now? Has anyone encountered this before?

My theory is that the bad connection in the combination switch (the original cause of the intermittent retracting), caused the wiring to short out somewhere on the red path. But that seems so unlikely! How can wiring just short out? Wouldn't a fuse blow? (Again, I've tested all fuses)

Please help RX-7 wizards!

Diagram taken from 1982 wiring diagram, which can be found here: http://www.wankel.net/~krwright/cars/rx7/manuals.html

Last edited by rotordave; 01-06-09 at 06:10 PM. Reason: url

#2

Howdy!

Well, you've only done continuity checks so far. There are some other chcecks that you can do that will tell you more specifically where the problem is at. Namely voltage checks.

Follow the center line to the combo switch, check there for 12 volts. Put the red lead on the spots I say to check and make sure the black lead is on a good ground. If all is good then there should be voltage (+12) there. Make sure you are looking for DC voltage! (Sorry, I've seen some of my students use the amperage setting and blow fuses.)

After that check the other side of the combo switch, again you're looking for 12 volts. If it's not there, then the issue is the combo switch. If it's there then coninue down the wire.

Check both sides of the switch, (E-02 and X-02). Basically where you have the blue line at and then again where the red line starts. When you do this one, do it with the switch in both positions. This will insure that the switch is good.

My best guess would be to look at that switch very carefully. Wires rarely go bad unless there is something rubbing on them, or a traumatic event happened. You might even want to pull the switch out and test it for continuity. With the switch in one position, one side should be closed when the other side is open. In the other position it should be reversed.

Who knows, maybe the act of pulling the switch out and putting it back in may give the connectors a new lease on life. I've seen it happen.

Post back the results, This is a partial list of things you can do, I don't want to overdo things. I'm more than happy to help troubleshoot things.

Well, you've only done continuity checks so far. There are some other chcecks that you can do that will tell you more specifically where the problem is at. Namely voltage checks.

Follow the center line to the combo switch, check there for 12 volts. Put the red lead on the spots I say to check and make sure the black lead is on a good ground. If all is good then there should be voltage (+12) there. Make sure you are looking for DC voltage! (Sorry, I've seen some of my students use the amperage setting and blow fuses.)

After that check the other side of the combo switch, again you're looking for 12 volts. If it's not there, then the issue is the combo switch. If it's there then coninue down the wire.

Check both sides of the switch, (E-02 and X-02). Basically where you have the blue line at and then again where the red line starts. When you do this one, do it with the switch in both positions. This will insure that the switch is good.

My best guess would be to look at that switch very carefully. Wires rarely go bad unless there is something rubbing on them, or a traumatic event happened. You might even want to pull the switch out and test it for continuity. With the switch in one position, one side should be closed when the other side is open. In the other position it should be reversed.

Who knows, maybe the act of pulling the switch out and putting it back in may give the connectors a new lease on life. I've seen it happen.

Post back the results, This is a partial list of things you can do, I don't want to overdo things. I'm more than happy to help troubleshoot things.

#3

I love RX-7s

Thread Starter

iTrader: (1)

Join Date: Jul 2007

Location: Sydney

Posts: 238

Likes: 0

Received 0 Likes

on

0 Posts

Thanks kencunm.

As far as testing continuity goes, I have tested everywhere the green is on the diagram. That means I have also tested the switch, and the combination switch (at least as far as the retractors are concerned) - you can see the green/orange lines go through the switches - this was to indicate the switches have been tested. In the case of the combination switch, I know it is bad, but fixing it won't be enough because of the continuity failing down the line.

I don't understand why testing for voltage will help find the problem. Surely if the continuity test fails anywhere between the power source and the motors then there is no connection and the wires will carry no voltage? So far I have been testing with the battery disconnected, which I'm more comfortable with!

In my case, the red part of the wiring shows no continuity between the switch and the retractor junction. Why would testing for voltage help? Far as I understand, testing for voltage is the same as testing for continuity between the battery terminals and the test point.

Don't get me wrong, I'm open to new ideas, and thats why I've posted.

Appreciate your advice.

As far as testing continuity goes, I have tested everywhere the green is on the diagram. That means I have also tested the switch, and the combination switch (at least as far as the retractors are concerned) - you can see the green/orange lines go through the switches - this was to indicate the switches have been tested. In the case of the combination switch, I know it is bad, but fixing it won't be enough because of the continuity failing down the line.

I don't understand why testing for voltage will help find the problem. Surely if the continuity test fails anywhere between the power source and the motors then there is no connection and the wires will carry no voltage? So far I have been testing with the battery disconnected, which I'm more comfortable with!

In my case, the red part of the wiring shows no continuity between the switch and the retractor junction. Why would testing for voltage help? Far as I understand, testing for voltage is the same as testing for continuity between the battery terminals and the test point.

Don't get me wrong, I'm open to new ideas, and thats why I've posted.

Appreciate your advice.

#4

Senior Member

iTrader: (4)

Join Date: Feb 2001

Location: Richmond, KY

Posts: 460

Likes: 0

Received 0 Likes

on

0 Posts

I had a similar problem on my 83. My lights wouldn't go up. It ended up being the ground wires on the retractors. I don't know if the wires got old or what, but I made new ground wires and haven't had a problem since.

#6

RotorDave

Checking for voltage will tell you if there are other issues.

When you troubleshoot something you ideally want to do it when things are in as close as possible to the operating conditions. By disconnecting the battery you are taking that part of the equation out and may miss something.

It's possible that something is preventing the voltage from getting up to an actuation level. This can't be checked with continuity, having the more definitive voltages would be more helpful. But if you aren't comfortable with it, then don't kill yourself just cuz I say so.

My suggestion is to go back to those spots and write down the voltages with the switch in both positions. You may even want to watch it while waiting for the lights to go down.

Ooohh, just thought of another possibility. Look at the connections at the bottom of the red line section. If there is a solder connection you might want to redo it. We already know the soldering techniques used in these cars was sub-standard.

Checking for voltage will tell you if there are other issues.

When you troubleshoot something you ideally want to do it when things are in as close as possible to the operating conditions. By disconnecting the battery you are taking that part of the equation out and may miss something.

It's possible that something is preventing the voltage from getting up to an actuation level. This can't be checked with continuity, having the more definitive voltages would be more helpful. But if you aren't comfortable with it, then don't kill yourself just cuz I say so.

My suggestion is to go back to those spots and write down the voltages with the switch in both positions. You may even want to watch it while waiting for the lights to go down.

Ooohh, just thought of another possibility. Look at the connections at the bottom of the red line section. If there is a solder connection you might want to redo it. We already know the soldering techniques used in these cars was sub-standard.

#7

How ya doin'?

Wouldn't be a "short," or you'd be blowing fuses. This has the smell of an intermittent open somewhere in the harness, along your red path.

The only ways I can think of that the harness wiring could fail intermittent open, would be:

1) Harness got pinched somewhere. There's a likely place where the harness routing shares space with the left-hand hood hinge (routing probably dfferent on RHD cars). When wires get pinched, they can break in very surprising ways, including the insulation being fine but the conductor crimped but occasionally touching. Heat can play a part, too, as copper and plastic both expand and contract to some degree with heat. You can also rarely see a failure where voltage (and continuity) is present, but not enough of the wire's diameter remains to carry enough current to make the part work, because the wire is MOSTLY cut, but sometimes touches. Those can make you mad. They usually end up just failing completely, after which locating them is easier. Nothing worse than chasing an intermittent problem.

2) Somewhere inside the harness, there is a point where that one RY wire is split to feed the two lights. I saw a few of these junctures when I refurbed my harness, years ago; they are done either with an insulated crimp connector, or a tape-wrapped solder junction (Ken touched on this). If that juncture was corroded, cracked, or failing, you could see similar symptoms. Sad part is, you might have to untape a goodly portion of your harness to find that junction, as there's no external indication of where it is. Logic would put it close to the point where the harness splits from one light to the other.

Oh, yes; on some mfg's harnesses, they have a white tag that sticks out thru the tape wrap, where ever they have a junction, specifically to make locating them easier. I don't remember if my original harness had these or not, though. Been 5 years since I retaped mine.

Wouldn't be a "short," or you'd be blowing fuses. This has the smell of an intermittent open somewhere in the harness, along your red path.

The only ways I can think of that the harness wiring could fail intermittent open, would be:

1) Harness got pinched somewhere. There's a likely place where the harness routing shares space with the left-hand hood hinge (routing probably dfferent on RHD cars). When wires get pinched, they can break in very surprising ways, including the insulation being fine but the conductor crimped but occasionally touching. Heat can play a part, too, as copper and plastic both expand and contract to some degree with heat. You can also rarely see a failure where voltage (and continuity) is present, but not enough of the wire's diameter remains to carry enough current to make the part work, because the wire is MOSTLY cut, but sometimes touches. Those can make you mad. They usually end up just failing completely, after which locating them is easier. Nothing worse than chasing an intermittent problem.

2) Somewhere inside the harness, there is a point where that one RY wire is split to feed the two lights. I saw a few of these junctures when I refurbed my harness, years ago; they are done either with an insulated crimp connector, or a tape-wrapped solder junction (Ken touched on this). If that juncture was corroded, cracked, or failing, you could see similar symptoms. Sad part is, you might have to untape a goodly portion of your harness to find that junction, as there's no external indication of where it is. Logic would put it close to the point where the harness splits from one light to the other.

Oh, yes; on some mfg's harnesses, they have a white tag that sticks out thru the tape wrap, where ever they have a junction, specifically to make locating them easier. I don't remember if my original harness had these or not, though. Been 5 years since I retaped mine.

Trending Topics

#8

I love RX-7s

Thread Starter

iTrader: (1)

Join Date: Jul 2007

Location: Sydney

Posts: 238

Likes: 0

Received 0 Likes

on

0 Posts

OK, I'll attempt to check for voltage. I still don't see how it will help though.

I *know* the combination switch is bad. Testing for voltage at the combination switch will tell me what I already know - it doesn't consistently carry 12 volts. I need to futz with the stalk to get a result.

And checking for voltage "downstream" of the red path will yield 0 volts. Infinite resistance won't carry electrons.

But I'm no electrician, so maybe I shouldn't second guess you blokes.

Now lets see if I can't blow myself and my car up

I *know* the combination switch is bad. Testing for voltage at the combination switch will tell me what I already know - it doesn't consistently carry 12 volts. I need to futz with the stalk to get a result.

And checking for voltage "downstream" of the red path will yield 0 volts. Infinite resistance won't carry electrons.

But I'm no electrician, so maybe I shouldn't second guess you blokes.

Now lets see if I can't blow myself and my car up

#9

Don't worry; the fuse'll pop once you're on fire... no explosions

Check for voltage on the harness side of X-02, on the RY wire. If it's there, your problem is downstream of there. if it's not, your problem is upstream of there.

If there's good voltage at X-02, I'd then physically inspect the harness, rather than hunting more voltages: you know the connect between the two motors is good, and you know things are good down to and past the manual retract switch.

Can't really be much else, since your blue bypass worked. You'll have to untape some harness, but retaping is easy enough.

Check for voltage on the harness side of X-02, on the RY wire. If it's there, your problem is downstream of there. if it's not, your problem is upstream of there.

If there's good voltage at X-02, I'd then physically inspect the harness, rather than hunting more voltages: you know the connect between the two motors is good, and you know things are good down to and past the manual retract switch.

Can't really be much else, since your blue bypass worked. You'll have to untape some harness, but retaping is easy enough.

#10

I love RX-7s

Thread Starter

iTrader: (1)

Join Date: Jul 2007

Location: Sydney

Posts: 238

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for your reply DivinDriver.

Checked the voltages at the switch connector E-02. I got 12.3 with the lights off, 11.8 with the parkers/running lights turned on, and 0 volts with the headlights on. So as you'd expect.

Plugged in the retractable headlight switch, and tested for voltage at the retractor motor connector E-04. Got 0 volts. As expected

I tried rattling and nudging the harness and the connector to see if i'd get voltage but no luck.

Checked the voltages at the switch connector E-02. I got 12.3 with the lights off, 11.8 with the parkers/running lights turned on, and 0 volts with the headlights on. So as you'd expect.

Plugged in the retractable headlight switch, and tested for voltage at the retractor motor connector E-04. Got 0 volts. As expected

I tried rattling and nudging the harness and the connector to see if i'd get voltage but no luck.

#11

So, you know the problem is somewhere between E-02 and E-04... X-02 is the logical half-step. You should be able to probe it without having to disconnect anything, by sliding the probe tip up along the wire into the connector.

Electrical troubleshooting like this is a matter of "divide and conquer."

PS: if X-02 is too hard to get to (it's way up in there), consider untaping the harness where it comes into theengine compartment, finding RY, and poking a sharp straight pin carefully thru the insulation so you can meter it there.

A small pinhole in the insulation will just close back up again, and you can retape the harness after.

So long as you don't let the pin touch ground or anything else, there's truly no danger.

Electrical troubleshooting like this is a matter of "divide and conquer."

PS: if X-02 is too hard to get to (it's way up in there), consider untaping the harness where it comes into theengine compartment, finding RY, and poking a sharp straight pin carefully thru the insulation so you can meter it there.

A small pinhole in the insulation will just close back up again, and you can retape the harness after.

So long as you don't let the pin touch ground or anything else, there's truly no danger.

#12

I love RX-7s

Thread Starter

iTrader: (1)

Join Date: Jul 2007

Location: Sydney

Posts: 238

Likes: 0

Received 0 Likes

on

0 Posts

Well considering I have already tested everything for continuity, including X-02 (so I know how hard it is to get there), I can be certain that there will be voltage at X-02.

If I'm going to start untaping the harness, wouldn't it be better to check at the junction for the other retractor, as we discussed before? Except maybe thats not as easy to get to.

Sticking pins into wires, now we're getting serious!

If I'm going to start untaping the harness, wouldn't it be better to check at the junction for the other retractor, as we discussed before? Except maybe thats not as easy to get to.

Sticking pins into wires, now we're getting serious!

#13

Well, it's a lot easier to get to the harness near the headlight retractors, yes.

The idea of checking near the firewall was that it was a good standing for X-02... next closest accessible point. It would tell you if the problem is under the dash, or in the engine bay.

Your problem is almost certainly either immediately at the junction, or "upstream" of it... because you have continuity between the two retractors, so the junction must be at least partially intact.

Look for visible abrasions/pinches/etc first, all along the harness from retractors back. You might get lucky and find a damage point.

If not, well, you just have to pick the first spot to test, and then follow the symptom (upstream) or lack of downstream). Junction is physically easier, probably. Less wires down there.

Good luck.

Too bad you don't have a tone generator/tracer. They are wizard devices for this type of stuff; connect it to the dead circuit (battery disconnected), and follow the tone til it stops.

But they cost money. Tape, and time, are cheap.

The idea of checking near the firewall was that it was a good standing for X-02... next closest accessible point. It would tell you if the problem is under the dash, or in the engine bay.

Your problem is almost certainly either immediately at the junction, or "upstream" of it... because you have continuity between the two retractors, so the junction must be at least partially intact.

Look for visible abrasions/pinches/etc first, all along the harness from retractors back. You might get lucky and find a damage point.

If not, well, you just have to pick the first spot to test, and then follow the symptom (upstream) or lack of downstream). Junction is physically easier, probably. Less wires down there.

Good luck.

Too bad you don't have a tone generator/tracer. They are wizard devices for this type of stuff; connect it to the dead circuit (battery disconnected), and follow the tone til it stops.

But they cost money. Tape, and time, are cheap.

#14

OK so how creepy is this? I went out and tried the same thing with my 83 GS and it's doing something close to what yours is. Works fine with the light switch but if I use the lamp up and down switch, it goes up fine, but takes it's sweet time going back down. I walked away and came back and it was down.

Looks like I'll be doing the same checks as you when I get some time. I've never used that switch before, just turned on the lights or turned the lights off, and never noticed any delay.

I'll get back to you if I find out, but it may be a while before I can get to it, I'm booked for the next few days.

Looks like I'll be doing the same checks as you when I get some time. I've never used that switch before, just turned on the lights or turned the lights off, and never noticed any delay.

I'll get back to you if I find out, but it may be a while before I can get to it, I'm booked for the next few days.

#15

I love RX-7s

Thread Starter

iTrader: (1)

Join Date: Jul 2007

Location: Sydney

Posts: 238

Likes: 0

Received 0 Likes

on

0 Posts

Sorry to hear that kencunm. I hope you don't have to go through the same crap.

So I started untaping the harness and sticking pins into the RY wires, and everything I learned since my original troubleshooting is making sense (unfortunately).

I got mislead by another RY wire that split just before the retractor/headlight branch. I undid all the insulation tape only to find after testing that it was another RY altogether, going to the headlight... so that was alot of time wasted.

But I did learn that rather than splitting before the retractor/headlight branch, its further up, which is a waste of wire if nothing else. Bloody Mazda.

I then began stipping off the tape further up the harness, and got halfway across the cross-member in front of the radiator and STILL cannot find the junction!!! Extremely frustrating.

So I need to trace these two RY wires (one which connects the retractors together, the other that comes from the retractor switch) until I find where they join, which is getting harder. I'm wondering if I should have started at the left retractor!

I'll keep you updated.

So I started untaping the harness and sticking pins into the RY wires, and everything I learned since my original troubleshooting is making sense (unfortunately).

I got mislead by another RY wire that split just before the retractor/headlight branch. I undid all the insulation tape only to find after testing that it was another RY altogether, going to the headlight... so that was alot of time wasted.

But I did learn that rather than splitting before the retractor/headlight branch, its further up, which is a waste of wire if nothing else. Bloody Mazda.

I then began stipping off the tape further up the harness, and got halfway across the cross-member in front of the radiator and STILL cannot find the junction!!! Extremely frustrating.

So I need to trace these two RY wires (one which connects the retractors together, the other that comes from the retractor switch) until I find where they join, which is getting harder. I'm wondering if I should have started at the left retractor!

I'll keep you updated.

#16

You'd think they would do the split as close as possible to the physical "Y", to save wire. How odd.

And needless to say, it was rude of them to have two conductors with the same color code in the same harness.

Only one wire comes out of the downstream side of X-02, right? (I haven't actually looked at mine)

For what it's worth, my manual retract switch works immediately, both ways... so the delayed retract isn't a "design feature."

And needless to say, it was rude of them to have two conductors with the same color code in the same harness.

Only one wire comes out of the downstream side of X-02, right? (I haven't actually looked at mine)

For what it's worth, my manual retract switch works immediately, both ways... so the delayed retract isn't a "design feature."

#17

I love RX-7s

Thread Starter

iTrader: (1)

Join Date: Jul 2007

Location: Sydney

Posts: 238

Likes: 0

Received 0 Likes

on

0 Posts

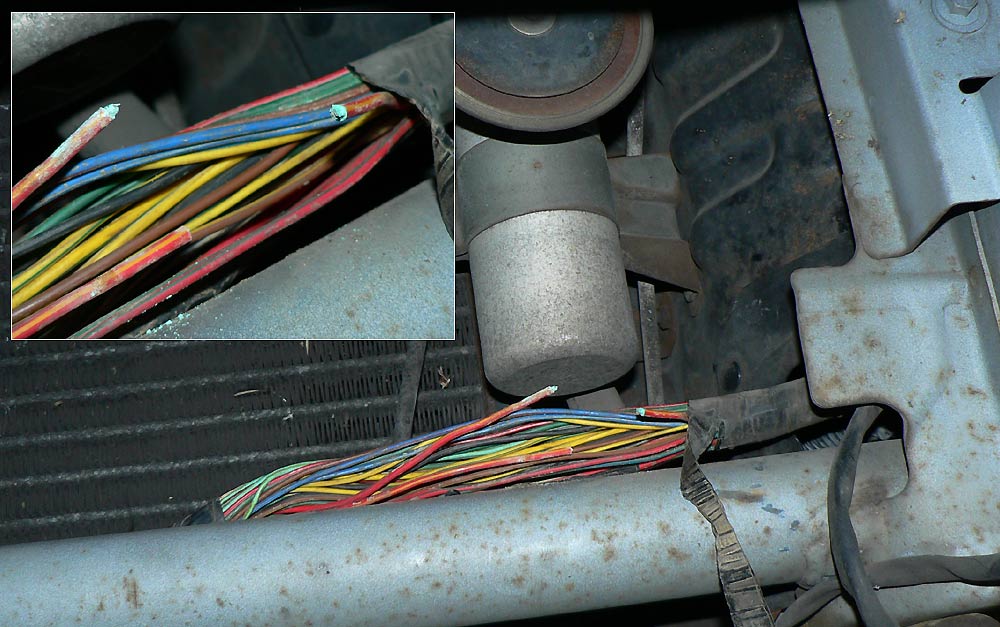

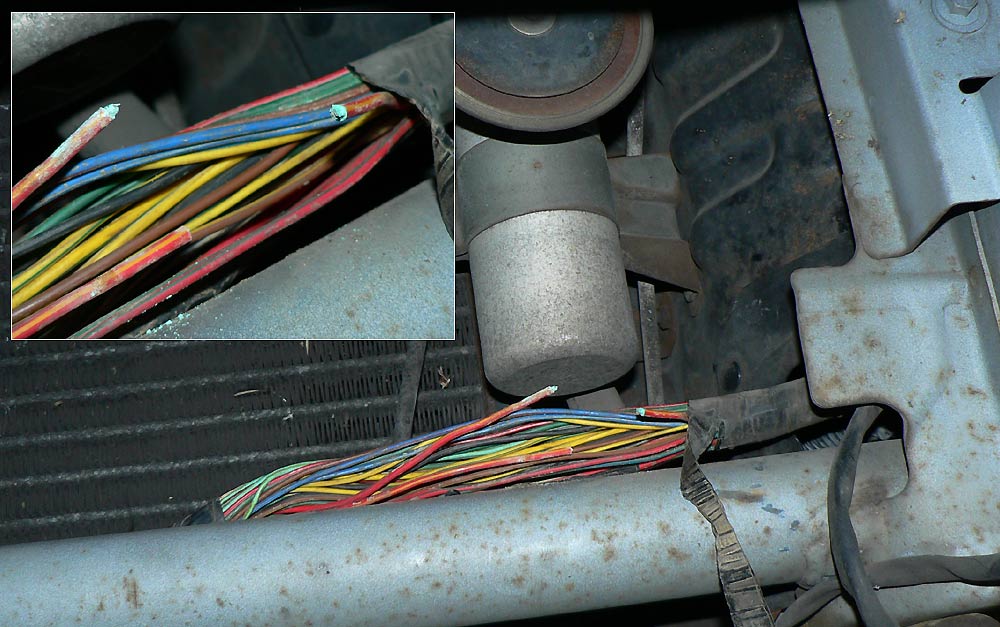

I've attached a photo of the area that I found the "phantom" junction that turned out to be something unrelated. You can see the E-04 connector in the foreground on the right. Since taking the photo all that has been untaped and is a mess.

Notice Mazda didn't even solder the split, just crimped it! They did wrap it in insulation tape at least.

#19

I love RX-7s

Thread Starter

iTrader: (1)

Join Date: Jul 2007

Location: Sydney

Posts: 238

Likes: 0

Received 0 Likes

on

0 Posts

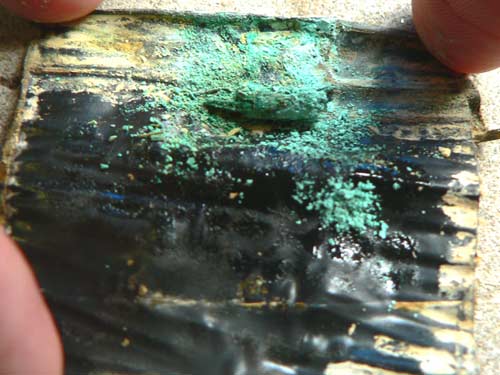

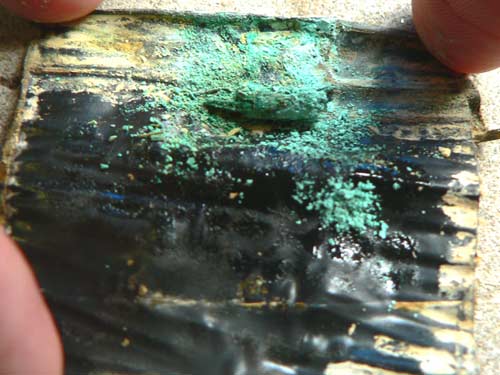

Look what I found:

And the "connection" for those three wires:

I'd like to know how that happened. I'll probably have to check the other junctions around that area for the same thing.

So now I need to strip them back till I find copper and get some more wire to bridge the gap, then start taping the whole thing back up.

And the "connection" for those three wires:

I'd like to know how that happened. I'll probably have to check the other junctions around that area for the same thing.

So now I need to strip them back till I find copper and get some more wire to bridge the gap, then start taping the whole thing back up.

#21

That's the harness section that crosses in front of the radiator, on that round bar you can see thru the grille; you can see one horn and the AC drier above it.

That's be your problem, looks like salt water or something got thru the tape wrap, and corroded the connector and some of the wires clean away. The Chlorox looking stuff is copper oxide, or possibly copper chloride... all that's left of your crimp connector.

Could have been something as simple as an unlucky rock hit that tore the tape in just the wrong place, then got wet whenever you drove in the rain.

Congrats... you are now a certified electrical troubleshooter!

Make sure when you replace the splice, that you trim back enough wire that no corrosion is visible. That stuff's like cancer; it attracts water which accelerates the corrosion.

Absolutely test before re-taping. And make sure you use good heavy wire for the replacement section.

That's be your problem, looks like salt water or something got thru the tape wrap, and corroded the connector and some of the wires clean away. The Chlorox looking stuff is copper oxide, or possibly copper chloride... all that's left of your crimp connector.

Could have been something as simple as an unlucky rock hit that tore the tape in just the wrong place, then got wet whenever you drove in the rain.

Congrats... you are now a certified electrical troubleshooter!

Make sure when you replace the splice, that you trim back enough wire that no corrosion is visible. That stuff's like cancer; it attracts water which accelerates the corrosion.

Absolutely test before re-taping. And make sure you use good heavy wire for the replacement section.

#22

I love RX-7s

Thread Starter

iTrader: (1)

Join Date: Jul 2007

Location: Sydney

Posts: 238

Likes: 0

Received 0 Likes

on

0 Posts

Problem solved, my headlights now go down!

My brother and I started by cutting back the wire until we found good copper. We ended up trimming more than 3 foot of wire to get rid of the corrosion!

Interestingly, the corrosion was far worse on the side of the wire that still carried electricity. Something to do with ions and anions, I guess.

As I had planned, we also checked the connections for other junctions around the area and found that a few of them were also suffering from corrosion, and were on their way out. We ended up rewiring and resoldering five or six other places along the harness. We also used heat shrink where possible, so the thing should be far more resistant in future. It surprises me that Mazda chose to run the wiring in the front like that - it would have been better to run it on top of the radiator shroud, or even inside the cross-member.

Taping it up wasn't easy, getting it straight and back to where it was before. But its done now.

I'll never take my headlights retracting for granted ever again now.

Hope this information is useful to other people, because it sounds like quite a few have had the same symptoms that point to bad wiring.

Thanks for all your help.

My brother and I started by cutting back the wire until we found good copper. We ended up trimming more than 3 foot of wire to get rid of the corrosion!

Interestingly, the corrosion was far worse on the side of the wire that still carried electricity. Something to do with ions and anions, I guess.

As I had planned, we also checked the connections for other junctions around the area and found that a few of them were also suffering from corrosion, and were on their way out. We ended up rewiring and resoldering five or six other places along the harness. We also used heat shrink where possible, so the thing should be far more resistant in future. It surprises me that Mazda chose to run the wiring in the front like that - it would have been better to run it on top of the radiator shroud, or even inside the cross-member.

Taping it up wasn't easy, getting it straight and back to where it was before. But its done now.

I'll never take my headlights retracting for granted ever again now.

Hope this information is useful to other people, because it sounds like quite a few have had the same symptoms that point to bad wiring.

Thanks for all your help.

#23

Good on ya, Dave. Time for a cold one.

You had electrolysis going on inside the jacket, essentially. Electrolytic corrosion will travel a wire under the insulator, and it feeds on itself; as the corrosion progresses, it increases resistance, which increases heat, which speeds the reaction. It also increases the conductor diameter (the oxides are spongy), allowing for more air and moisture to enter the jacket.

You had electrolysis going on inside the jacket, essentially. Electrolytic corrosion will travel a wire under the insulator, and it feeds on itself; as the corrosion progresses, it increases resistance, which increases heat, which speeds the reaction. It also increases the conductor diameter (the oxides are spongy), allowing for more air and moisture to enter the jacket.

Thread

Thread Starter

Forum

Replies

Last Post